Top 8 Mayonnaise Filling Machine Manufacturers

Top 8 Mayonnaise Filling Machine Manufacturers

In the world of food packaging, efficiency, precision, and hygiene are paramount, especially when it comes to filling bottles with condiments like mayonnaise. Mayonnaise filling machine and their counterparts, such as hot sauce bottle filler or sauce bottle filler, are essential components in the production line. But what exactly is a filler machine, how does it work, and what types are available? Let's explore these questions to unravel the intricacies of bottle filling machines.

What is a Filler Machine?

A filler machine, also known as a bottle filler or filling machine, is a specialized equipment designed to accurately dispense liquid or semi-liquid substances into bottles or containers. These machines streamline the packaging process, ensuring consistent filling volumes and minimizing product waste.

How Does a Bottle Filler Work?

A bottle filler operates on a straightforward principle:

1. Bottle Preparation: Empty bottles are loaded onto the machine's conveyor belt or manually placed into holders.

2. Filling: The substance, such as mayonnaise or sauce, is pumped or gravity-fed into the bottles through filling nozzles, controlled by valves to maintain precise filling volumes.

3. Capping: Once filled, the bottles are securely capped to seal the contents and prevent leakage.

4. Labeling and Packaging: Some advanced machines may incorporate labeling and packaging functions to prepare the filled bottles for distribution.

What are the Different Types of Bottle Filling Machines?

Bottle filling machines come in various types to cater to different products and production needs:

1. Overflow Filling Machines: Ideal for filling liquids with low viscosity, such as water or juice, these machines ensure precise filling levels by allowing excess liquid to overflow.

2. Piston Filling Machines: Suitable for thicker substances like mayonnaise or sauce, these machines use piston-driven cylinders to accurately dispense product into bottles.

3. Gravity Filling Machines: Utilizing gravity, these machines fill bottles from the bottom up, making them suitable for filling foamy or carbonated liquids.

4. Volumetric Filling Machines: These machines employ predetermined volumes of product to fill containers, ensuring consistent filling levels.

5. Net Weight Fillers: Designed to fill bottles based on weight, these machines are ideal for products sold by weight, such as honey or jam.

6. Rotary Filling Machines: With a rotary indexing system, these machines offer high-speed filling capabilities, making them suitable for large-scale production lines.

7. Pressure Filling Machines: Suitable for carbonated beverages or sauces, these machines fill bottles under pressure to maintain carbonation or prevent product degradation.

8. Vacuum Filling Machines: These machines remove air from the bottle before filling, minimizing oxidation and preserving product freshness.

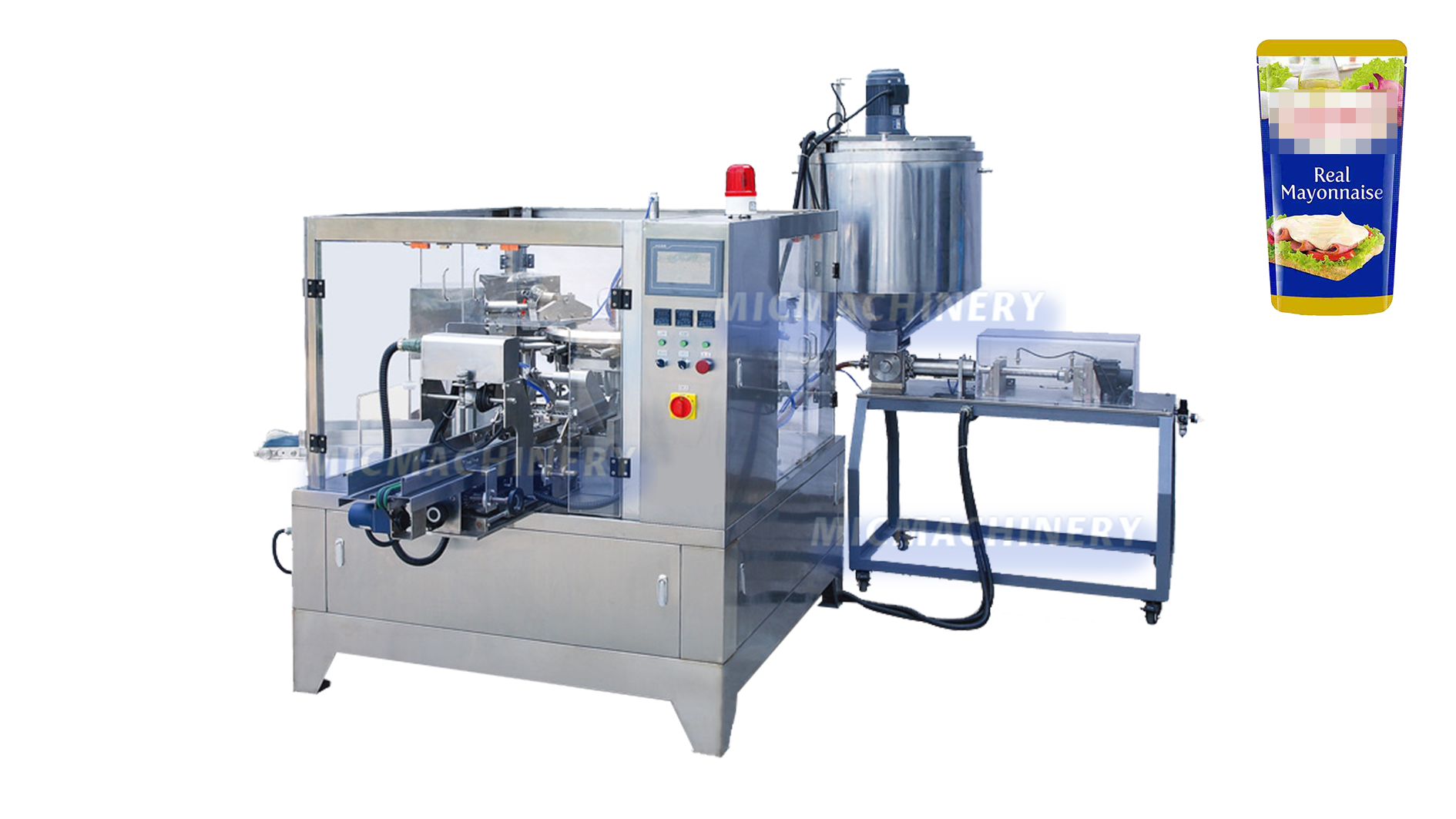

When it comes to choosing a reliable mayonnaise filling machine manufacturer, it's essential to partner with reputable companies known for their expertise and quality craftsmanship. Among the myriad of options, mayonnaise automatic filling machine suppliers such as Mic Machinery stand out for their commitment to innovation and customer satisfaction. With a proven track record in delivering high-performance machines, Mic Machinery and other leading tomato sauce bottle filler and bbp sauce bottle filler manufacturers offer a comprehensive range of solutions tailored to meet diverse production needs.

List of 8 Mayonnaise Filling Machine Manufacturers

Renowned for its expertise in beverage filling equipment, Mic Machinery also excels in the production of mayonnaise filling machine. Their solutions are designed to handle various viscosities and bottle sizes, ensuring consistent and precise filling of mayonnaise containers. Additionally, Mic Machinery offers hot sauce bottle filler and tomato sauce bottle filler to meet diverse customer needs.

ABC Filling Solutions is a trusted name in the food packaging industry, offering a range of sauce bottle fillers tailored to different applications. Their equipment is known for its reliability and efficiency, making it a preferred choice for mayonnaise and other sauce producers.

3. Filamatic ![]()

Specializing in liquid filling solutions, Filamatic provides versatile mayonnaise filling machines capable of handling a wide range of container sizes and shapes. Their expertise in precision filling ensures minimal product wastage and maximizes efficiency.

4. Filling Equipment Company, Inc. ![]()

With a focus on custom solutions, Filling Equipment Company, Inc. offers hot sauce bottle fillers and tomato sauce bottle fillers tailored to the specific requirements of each client. Their commitment to customer satisfaction sets them apart in the industry.

All-Fill Inc. is known for its comprehensive range of filling machinery, including bbp sauce bottle fillers designed to accommodate thick and chunky sauces like barbecue and marinara. Their equipment is engineered for high-speed and precision filling operations.

6. Accutek Packaging Equipment Companies, Inc. ![]()

Accutek provides state-of-the-art filling equipment suitable for a variety of liquids, including mayonnaise and other sauces. Their mayonnaise filling machines feature advanced technology for accurate dosing and sealing.

Offering customizable filling solutions, Inline Filling Systems caters to the unique needs of each client. Their sauce bottle fillers are renowned for their reliability and consistent performance in demanding production environments.

NPACK Machinery specializes in filling equipment for various industries, including food and beverage. Their range of mayonnaise automatic filling machines incorporates advanced automation features for increased productivity and efficiency.

In conclusion, bottle filling machines are indispensable assets in the food packaging industry, ensuring efficiency, accuracy, and product quality. By understanding the principles, types, and key considerations in choosing these machines, manufacturers can optimize their production processes and uphold the highest standards of quality and hygiene. Partnering with reputable suppliers like Mic Machinery ensures access to cutting-edge technology and reliable equipment, essential for staying competitive in the market.