Top 20 Soda Filling Machine Manufacturers in 2026

Top 20 Soda Filling Machine Manufacturers in 2026

The production of carbonated soft drinks is a symphony of precise ingredients and equally precise packaging. At the heart of this process is the soda filling machine, a specialized piece of equipment engineered to handle the unique challenge of containing fizz. For entrepreneurs and established brands alike, understanding this technology is the first step toward successful production. This guide answers foundational questions: what the machine is, what other equipment is required, and the financial entry point.

| Table of Contents |

| What is a Soda Filling Machine? |

| List of 20 Soda Filling Machine Manufacturers |

| List of 16 Soda Filling Products |

| Global Distribution of Soda Filling Machine Manufacturers by Country |

What is a Soda Filling Machine?

A soda filling machine is a specialized system designed to accurately dispense carbonated beverages into containers—primarily PET plastic bottles, glass bottles, or aluminum cans—without losing carbonation or introducing oxygen. It is not a simple pump; it is a precision instrument that manages pressure throughout the filling cycle. These machines range from manual units for startups to fully automated rotary lines for high-volume production, developed by specialized soda water filling machine manufacturers and PET soda filling machine manufacturers.

What Equipment is Needed to Make Soda?

A soda filling machine is just one critical component of a complete production line. To make soda from scratch, you typically need:

1. Water Treatment System: Purifies water to a consistent standard, removing minerals and contaminants.

2. CO₂ Gas Supply & Carbonator: Dissolves food-grade carbon dioxide into the treated water under high pressure.

3. Syrup Batching Tanks: For mixing flavor concentrates and sweeteners.

4. Proportioning/Mixing Unit: Precisely blends carbonated water with syrup to create the final beverage.

5. Soda Filling Machine: Fills the finished product into containers.

6. Capping Machine: Immediately seals the filled containers. Integrated units are offered by

soda filling and capping machine manufacturers.

7. Labeling & Packaging Equipment: For applying labels and packing bottles into cases.

How Much Does a Basic Soda Filling Machine Cost?

The cost of a basic soda filling machine depends heavily on the level of automation. For a new or small-scale operation, there are two primary paths:

• Semi-Automatic Machines: These require an operator to place each bottle and often trigger the fill cycle. They utilize

proper counter-pressure technology but are slower. The semi automatic soda filling machine manufacturers offer

these entry-level systems, with prices typically ranging from $15,000 to $50,000.

• Basic Automatic Machines: These are small, in-line systems that automate bottle conveyance and filling. A basic

automatic machine from automatic soda filling machine manufacturers represents a higher initial investment,

usually starting around $50,000 and going up to $150,000 for a complete fill-cap unit.

These figures are for the filler itself; a full, modest production line with water treatment, carbonation, and packaging will cost significantly more.

Filling Technology and Mechanisms: Counter-Pressure

The non-negotiable technology for carbonated soda is counter-pressure (isobaric) filling. The mechanism works in a precise sequence:

1. The empty bottle is sealed against the filling valve.

2. CO₂ is injected to pressurize the bottle, matching the pressure in the product tank.

3. The liquid valve opens. Because pressures are equal, the soda flows in smoothly without foaming.

4. After filling, the gas pressure in the bottle's neck is slowly released before the bottle is uncapped from the valve.

This technology is what separates professional soda filling equipment from simple liquid fillers.

Advantages and Benefits of Automated Filling Machines

Investing in a proper soda filler from reputable manufacturers delivers key advantages:

• Carbonation Preservation: Maintains the intended "fizz" level by preventing CO₂ breakout during filling.

• Speed and Scale: Enables production volumes that are impossible with manual methods.

• Hygiene and Safety: Built with food-grade stainless steel and often Clean-in-Place (CIP) systems.

• Fill Accuracy: Eliminates product giveaway by ensuring every container has the exact same volume.

• Oxygen Exclusion: Minimizes oxygen pickup, which protects flavor and extends shelf life.

• Professional Consistency: Creates a uniform, high-quality product that builds brand credibility.

Troubleshooting and Maintenance Considerations

Soda filling machines require diligent care due to their sensitivity to pressure and hygiene.

• Excessive Foaming: Check for warm product temperature, low CO₂ pressure in the tank, or worn/dirty filling valve

seals.

• Flat Product (Low Carbonation): Often caused by leaks in the CO₂ purging system or incorrect pressure settings.

• Leaky Valves or Dripping: Usually indicates worn O-rings or gaskets in the filling valves that need replacement.

• Inconsistent Fill Levels: Can result from clogged liquid nozzles or fluctuating product tank pressure.

A rigorous preventive maintenance schedule is essential. This includes daily cleaning (CIP), weekly inspection and lubrication, and scheduled replacement of valve seals and O-rings. Following the protocols provided by your equipment manufacturer—whether from semi automatic soda filling machine manufacturers or automatic soda filling machine manufacturers—is the best way to protect your investment and ensure years of reliable, quality production.

List of 20 Soda Filling Machine Manufacturers

|

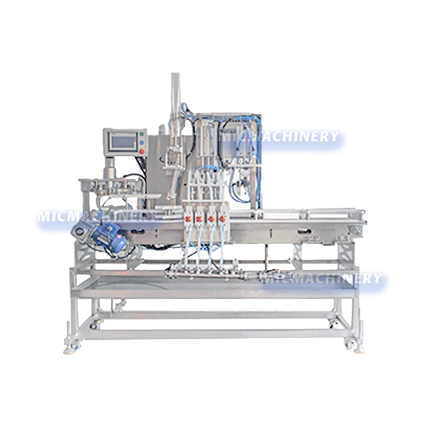

Address: Room 1905, Youyi Building, Xincheng Avenue, Cixi, Ningbo, Zhejiang, China |

|

| Mic Machinery is a leading provider of beverage production solutions, renowned for their high-precision can and bottle filling systems. They are recognized among top soda water filling machine manufacturers for delivering efficient, reliable, and customizable machines. Their soda filling lines are engineered for high-speed operations with minimal maintenance. Mic Machinery also offers comprehensive after-sales support to ensure long-term performance. |

|

Address: 152 Longquan Bay, Xueyan Town, Wujin, Changzhou, Jiangsu, China |

|

| BW Filling Machinery specializes in advanced beverage filling solutions for carbonated drinks. Their machines are designed for accurate volume control and rapid production speeds. The company has earned a reputation for robust construction and reliable performance. BW Filling Machinery lines are commonly used by both small-scale and industrial producers. |

|

Address: 2224 Wukesong Road, Sanxing town, Zhangjiagang, Jiangsu, China |

|

| Zhangjiagang Mic Machinery offers high-efficiency soda filling systems with strong durability. Their lines integrate automated controls for precision filling and quality assurance. The company emphasizes ease of cleaning and maintenance. Clients benefit from a global service network and spare parts availability. |

|

Address: Böhmerwaldstraße 5, 93073 Neutraubling, Bavaria, Germany |

|

| Krones is a global leader in beverage packaging technology and recognized as a top automatic soda filling machine manufacturers. Their equipment integrates high-speed filling with precise carbonation and temperature controls. Krones emphasizes energy efficiency and sustainable production processes. The company provides turnkey solutions for multinational beverage brands. |

|

Address: 1535 S State Road 39, La Porte, Indiana, United States of America |

|

| APACKS designs and manufactures flexible soda filling lines suitable for bottles and cans. Their systems are known for hygienic design, minimal product loss, and consistent quality. APACKS machines are widely used in high-volume beverage production. They also offer installation, training, and technical support services. |

|

Address: Avenue de la Patrouille de France, 76930 Octeville-sur-Mer, Normandy, France |

|

| Sidel supplies cutting-edge filling solutions for carbonated drinks, including soda bottles and cans. Their machines focus on reducing energy and water usage while maximizing throughput. Sidel emphasizes modular design to adapt to different production requirements. Their equipment is widely adopted in global beverage plants. |

|

Address: 50 Schoolhouse Road Somerset, New Jersey, United States of America |

|

| Cozzoli Machine Company provides specialized soda filling machines designed for both small-scale and industrial production. Their lines ensure precise filling, minimal foaming, and consistent carbonation levels. The company focuses on reliability and easy maintenance. Cozzoli systems are recognized for flexibility and long service life. |

|

Address: Stuttgarter Straße 130, Waiblingen, Baden-Württemberg, Germany |

||

| Syntegon Technology GmbH offers innovative beverage filling and packaging machinery for soda production. Their lines integrate automated controls for filling accuracy and process monitoring. Syntegon machines emphasize hygiene, energy efficiency, and operator-friendly interfaces. The company has a strong global presence for installation and support. |

|

Address: 4119 Fordleigh Road Baltimore, Maryland, United States of America |

||

| Filamatic is known for compact, high-speed beverage filling machines. Their soda filling lines can handle various bottle sizes with minimal product waste. The company emphasizes durability and easy operation. Filamatic systems are suitable for both commercial and industrial applications. |

|

Address: Juchostrasse 20, 44143 Dortmund, Germany |

|

| KHS GmbH provides complete soda filling and packaging solutions. Their lines are engineered for high-volume production, precise filling, and reliable operation. The company integrates sensors and advanced controls for accuracy and efficiency. KHS is a trusted name in sustainable beverage production. |

|

Address: 2980 Scott St, Vista, CA 92081, United States |

|

| Accutek Packaging Equipment specializes in high-performance beverage filling lines. Their machines are designed for fast production and precise fill control. Accutek emphasizes minimal downtime and easy maintenance. Their solutions are widely used in soft drink bottling plants worldwide. |

|

Address: Via Italia, 43, Gessate Milano, Lombardy, Italy |

|

| Ronchi Mario S.p.A. manufactures soda bottling and canning systems with a focus on precision engineering. Their machines combine hygiene, automation, and high-speed performance. They emphasize adaptability to client-specific production requirements. Ronchi Mario is recognized for Italian craftsmanship and long-lasting equipment. |

|

Address: Via G. Garibaldi, 34N, Bonate Sotto, Lombardy, Italy |

|

| Comac produces innovative beverage filling and packaging machinery for carbonated drinks. Their soda filling lines are designed to reduce product loss and optimize throughput. Comac emphasizes user-friendly interfaces and robust construction. Their systems are suitable for both small-scale and large beverage operations. |

|

Address: Olympus House, Mill Green Road, Haywards Heath, West Sussex, United Kingdom |

|

| Adelphi Packaging Machinery offers flexible soda filling lines for bottles and cans. Their machines provide precise filling and high production speeds. Adelphi emphasizes energy efficiency and reliability. They are recognized among top semi automatic soda filling machine manufacturers, offering lines that combine automation with manual operation for smaller production scales. |

|

Address: N15 W23500 Stone Ridge Drive, Waukesha, Wisconsin, United States of America |

||

| Federal Mfg. designs soda filling systems with high precision and minimal maintenance requirements. Their lines are recognized for durable components and consistent output. Federal Mfg. machines integrate simple operation with automated features. They are widely used in North American beverage plants. |

|

Address: Hofäckerstraße 9 Crailsheim, Baden-Württemberg, Germany |

|

|

Groninge produces specialized soda filling equipment focused on accuracy, hygiene, and reliability. Their lines ensure consistent carbonation and fill levels across production. The company emphasizes easy cleaning and long-term performance. Groninger equipment is suitable for both small and large-scale operations. |

|

Address: Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa, Japan |

|

| Shibuya Corporation offers high-speed soda filling and packaging machinery. Their systems focus on automation, product safety, and operational efficiency. Shibuya integrates smart control systems for consistent quality. Their machines are widely supported with global technical service. |

|

Address: 15-39 130th St, College Point, New York, United States of America |

|

| Filling Equipment Company delivers complete soda filling and capping machine manufacturers solutions for beverage producers. Their lines are known for speed, accuracy, and robust design. The company emphasizes reliability and ease of maintenance. Clients also receive guidance for installation and operation. |

|

Barry-Wehmiller Packaging Systems Address: 8020 Forsyth Boulevard, St. Louis, Missouri, United States of America |

||

| Barry-Wehmiller Packaging Systems specializes in soda filling systems designed for high-volume production. Their machines focus on efficiency, product safety, and consistent output. The company incorporates energy-saving technologies in their equipment. Barry-Wehmiller lines are widely adopted in the global beverage industry. |

|

Address: 1535 South State Road 39, La Porte, IN 46350, United States |

|

| E-PAK Machinery manufactures advanced beverage filling lines and is recognized as PET soda filling machine manufacturers for their PET bottle systems. Their equipment ensures precise fill control, hygienic design, and high throughput. E-PAK provides worldwide technical support and maintenance services. Their machines are known for reliability and long operational life. |

Global Distribution of Soda Filling Machine Manufacturers by Country

| Country | Number of Companies | Share (%) |

|

USA | 8 | 40% |

|

Germany | 4 | 20% |

|

China | 3 |

15% |

|

Italy | 2 | 10% |

|

France | 1 | 5% |

|

United Kingdom | 1 | 5% |

|

Japan | 1 | 5% |

List of 16 Soda Filling Machine Products

|

|

An 18-6 soda can filling machine is equipped with 18 filling heads and 6 sealing heads to efficiently fill and seal soda cans in one integrated process. It ensures accurate filling, hygienic operation, and high-speed production, making it ideal for medium to large-scale soda can manufacturing. |

|

|

|

|

12-12-1 Glass Bottle Soda Filling Machine

A 12-12-1 glass bottle soda filling machine is designed with 12 rinsing heads, 12 filling heads, and 1 capping head to complete bottle rinsing, soda filling, and capping in a single process. It ensures precise filling, hygienic operation, and stable performance, making it ideal for small to medium-scale glass bottle soda production. |

|

|

|

|

18-18-1 Glass Bottle Soda Filling Machine

An 18-18-1 glass bottle soda filling machine is equipped with 18 rinsing heads, 18 filling heads, and 1 capping head to complete bottle rinsing, soda filling, and capping in one integrated process. It ensures accurate filling, hygienic operation, and reliable performance, making it suitable for medium-scale glass bottle soda production. |

|

|

|

|

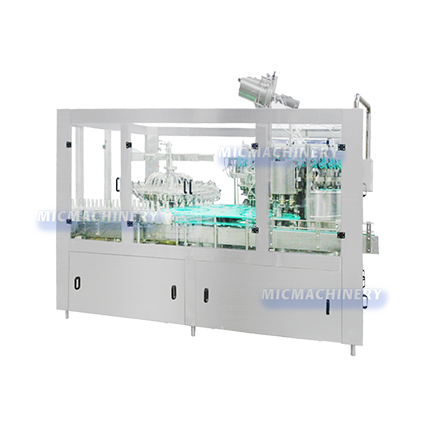

18-18-6 PET Bottle Soda Filling Machine

An 18-18-6 PET bottle soda filling machine is designed with 18 rinsing heads, 18 filling heads, and 6 capping heads to complete rinsing, filling, and capping of PET bottles in one line. It ensures precise soda filling, hygienic operation, and high efficiency, making it ideal for medium to large-scale PET bottle soda production. |

|

|

|

|

A 24-6 soda can filling machine is equipped with 24 filling heads and 6 sealing heads to efficiently fill and seal soda cans in one process. It ensures accurate dosing, hygienic operation, and high-speed production, making it ideal for large-scale soda can manufacturing. |

|

|

|

|

A 32-8 soda can filling machine comes with 32 filling heads and 8 sealing heads to fill and seal soda cans efficiently in one integrated process. It ensures precise dosing, hygienic operation, and high-speed production, making it ideal for large-scale soda can manufacturing. |

|

|

|

|

40-10 Soda Can Filling Machine

A 40-10 soda can filling machine is equipped with 40 filling heads and 10 sealing heads to efficiently fill and seal soda cans in one process. It ensures accurate dosing, hygienic operation, and high-speed production, making it ideal for large-scale soda can manufacturing. |

|

|

|

|

Small Soda Can Filling Machine

A small soda can filling machine is designed to fill and seal soda cans in smaller production lines. It ensures accurate dosing, hygienic operation, and efficient performance, making it ideal for small to medium-scale soda can manufacturing. |

|

|

|

|

Semi-auto Soda Can Seaming Machine

A semi-auto soda can seaming machine is used to manually place cans while automatically sealing them. It ensures tight, leak-proof seams, hygienic operation, and improved efficiency, making it suitable for small to medium-scale soda can production. |

|

|

|

|

A 12-1 soda can filling machine is equipped with 12 filling heads and 1 sealing head to efficiently fill and seal soda cans in one process. It ensures accurate dosing, hygienic operation, and stable performance, making it ideal for small to medium-scale soda can manufacturing. |

|

|

|

|

Semi-auto Soda Bottle Filling Machine

A semi-auto soda bottle filling machine is designed to partially automate the filling of soda into bottles. It combines manual handling with automated filling to ensure accurate dosing, hygienic operation, and improved efficiency, making it suitable for small to medium-scale soda production. |

|

|

|

|

Semi-auto Soda Can Filling Machine

A semi-auto soda can filling machine is designed to partially automate the filling of soda into cans. It combines manual operation with automated processes to ensure accurate dosing, hygienic filling, and improved efficiency, making it suitable for small to medium-scale soda can production. |

|

|

|

|

An 18-1 soda can filling machine is equipped with 18 filling heads and 1 sealing head to efficiently fill and seal soda cans in a single process. It ensures accurate dosing, hygienic operation, and stable performance, making it ideal for medium-scale soda can production. |

|

|

|

|

24-24-6 Glass Bottle Soda Filling Machine

A 24-24-6 glass bottle soda filling machine is designed with 24 rinsing heads, 24 filling heads, and 6 capping heads to complete rinsing, filling, and capping in one integrated process. It ensures accurate soda filling, hygienic operation, and high-speed performance, making it ideal for large-scale glass bottle soda production. |

|

|

|

|

18-18-1 Glass Soda Bottling Machine

An 18-18-1 glass soda bottling machine features 18 rinsing heads, 18 filling heads, and 1 capping head to complete rinsing, filling, and capping of glass soda bottles in one line. It ensures precise filling, hygienic operation, and reliable performance, making it ideal for medium-scale soda production. |

|

|

|

|

32-32-8 Glass Bottle Soda Filling Machine

A 32-32-8 glass bottle soda filling machine is equipped with 32 rinsing heads, 32 filling heads, and 8 capping heads to efficiently rinse, fill, and cap glass soda bottles in one integrated process. It ensures high-speed, precise filling, hygienic operation, and reliable performance, making it ideal for large-scale glass bottle soda production. |

|

|