Top 20 Soda Filling Machine Manufacturers in 2025

Top 20 Soda Filling Machine Manufacturers in 2025

The production of carbonated soft drinks is a precise science, blending flavor, carbonation, and packaging efficiency. At the heart of this operation lies the soda filling machine, a critical piece of equipment designed to tackle the unique challenge of containing fizz. For anyone entering the beverage industry, key questions arise: What types of soda fillers are available? What other equipment is needed? And how does the filling process itself work? This guide explores the technology, process, and benefits of automated soda filling.

What Equipment is Needed to Make Soda?

A complete soda production line involves more than just a filler. The essential equipment includes:

• Water Treatment System: Purifies water to a consistent standard.

• Syrup Batching Tanks: For mixing concentrate, sweeteners, and flavors.

• Carbonator: Dissolves CO₂ gas into the treated water under high pressure.

• Proportioner: Precisely blends carbonated water with syrup.

• Soda Filling Machine: The core unit that fills the blended, carbonated product into containers.

• Capping/Crowning Machine: Seals the bottles immediately after filling.

• Labeling and Packaging Equipment: For final product presentation.

What are the Different Types of Soda Filling Machines?

The choice of machine depends on production scale and automation needs. Key types include:

• Semi-Automatic Fillers: Operators place bottles on the filler head manually. Ideal for low-volume production, with a

lower semi automatic soda filling machine price that is accessible for startups.

• Automatic In-Line Fillers: Bottles are conveyed automatically under a bank of filling valves. These offer a balance of

speed and cost, influencing the overall automatic soda filling machine price.

• Rotary Fillers: The most efficient for high-volume output. Bottles travel around a circular carousel, undergoing filling

and capping in a continuous motion. These complex systems are the specialty of

rotary soda filling machine manufacturers.

All these types are supplied by specialized soda filling machine manufacturers, with some focusing on the critical technology of carbonation handled by soda gas filling machine manufacturers.

What is the Process of a Soda Filling Machine?

The filling process for carbonated beverages is designed to prevent loss of CO₂. The standard method is counter-pressure filling:

1. Bottle Cleaning: Empty bottles are inverted and purged with clean air or ionized air jets.

2. Purging: The clean bottle is sealed against the filling valve. CO₂ is injected to displace the air inside, creating a

pressure environment that matches the product tank.

3. Filling: The product valve opens, and the pressurized soda flows gently into the equally pressurized bottle. This

pressure equilibrium prevents foaming.

4. Decompression: The product valve closes, and the gas pressure in the bottle's headspace is slowly released (snifted)

to prevent violent foaming when the bottle is released.

5. Discharge: The filled bottle is conveyed to the capper for immediate sealing.

Filling Technology and Mechanisms: Counter-Pressure

Counter-pressure filling is non-negotiable for carbonated drinks. The filling valves are engineered with separate channels for gas and liquid. This allows for the precise control of pressure throughout the cycle, ensuring the dissolved CO₂ remains in solution. This technology is what defines modern soda filling equipment and is a key differentiator for leading soda filling machine manufacturers.

Advantages and Benefits of Automated Soda Bottling Machines

Investing in a dedicated soda filler offers significant advantages:

• Preserves Carbonation: Expertly manages pressure to ensure perfect fizz in every bottle.

• High Production Speed: Automates the most critical and delicate step, enabling large-scale output.

• Fill Accuracy: Eliminates product giveaway by ensuring precise volume control.

• Hygiene and Safety: Constructed from stainless steel with CIP systems to meet food safety standards.

• Reduced Operational Costs: Lowers labor requirements and minimizes product waste through spillage.

Troubleshooting and Maintenance Considerations

Proactive maintenance is essential for performance and longevity. Common issues include:

• Excessive Foaming: Caused by warm product temperature, incorrect CO₂ pressure, or worn valve seals.

• Low Fill Levels: Often a result of foaming or clogged filler bowls.

• Leaky Valves: Typically solved by replacing worn O-rings or gaskets.

A strict preventive maintenance schedule from the soda filling machine manufacturers is crucial. This protects your investment, regardless of the initial soda filling machine price, by ensuring consistent quality and minimizing costly downtime.

List of 20 Soda Filling Machine Manufacturers

|

Address: Room 1905, Youyi Building, Xincheng Avenue, Cixi, Ningbo, Zhejiang, China |

|

| Mic Machinery is one of the most reliable soda filling machine manufacturers, providing complete filling and packaging solutions for the beverage industry. The company specializes in both automatic and semi-automatic systems, making it a strong competitor in global markets. Customers value its flexibility, offering solutions that meet both automatic soda filling machine price and semi automatic soda filling machine price requirements. |

|

Address: 152 Longquan Bay, Xueyan Town, Wujin, Changzhou, Jiangsu, China |

|

| BW Filling Machinery is recognized as one of the advanced soda gas filling machine manufacturers, focusing on accurate carbonation and hygienic filling solutions. Their systems are designed to optimize efficiency while ensuring product quality. BW Filling Machinery’s wide range of machines also makes them competitive in terms of automatic soda filling machine price. |

|

Address: 2224 Wukesong Road, Sanxing town, Zhangjiagang, Jiangsu, China |

|

| Zhangjiagang Mic Machinery ranks among Asia’s leading soda filling machine manufacturers, known for their efficient and durable filling systems. Their machines are used by both domestic and international soda brands. Zhangjiagang Mic Machinery also provides competitive soda filling machine price models for businesses of all sizes. |

|

Address: Böhmerwaldstraße 5, 93073 Neutraubling, Bavaria, Germany |

|

| Krones is a global leader among rotary soda filling machine manufacturers, with decades of experience in beverage technology. Known for high precision and German engineering, their machines serve some of the largest soda brands worldwide. Krones also offers innovative systems tailored to meet different soda filling machine price ranges. |

|

Address: 1535 S State Road 39, La Porte, Indiana, United States of America |

|

| APACKS is well-established among rotary soda filling machine manufacturers, delivering solutions for both PET and glass bottle applications. Their technology ensures precise carbonation levels, extending shelf life for soda products. The company also offers cost-effective machines that meet various semi automatic soda filling machine price expectations. |

|

Address: Avenue de la Patrouille de France, 76930 Octeville-sur-Mer, Normandy, France |

|

| Sidel is one of the top soda filling machine manufacturers, offering complete production line solutions for global beverage companies. Their rotary systems provide excellent filling accuracy and efficiency. With competitive soda filling machine price options, Sidel supports both high-volume producers and mid-sized businesses. |

|

Address: 50 Schoolhouse Road Somerset, New Jersey, United States of America |

|

| Cozzoli Machine Company is another leading brand among rotary soda filling machine manufacturers, providing high-speed filling lines for carbonated beverages. Their systems emphasize automation and reliability, ensuring long-term performance. Cozzoli also adapts machines to match global automatic soda filling machine price standards. |

|

Address: Stuttgarter Straße 130, Waiblingen, Baden-Württemberg, Germany |

||

| Syntegon Technology GmbH is a trusted name in soda filling machine manufacturers, offering modular filling solutions for sodas and other beverages. Their semi-automatic and rotary models are highly flexible. Syntegon also supports smaller businesses with machines aligned with semi automatic soda filling machine price ranges. |

|

Address: 4119 Fordleigh Road Baltimore, Maryland, United States of America |

||

| Filamatic is a well-known company among soda gas filling machine manufacturers, offering compact and portable systems for smaller producers. Their machines are especially popular in North America’s craft beverage sector. Filamatic also provides accessible soda filling machine price options for startups. |

|

Address: Juchostrasse 20, 44143 Dortmund, Germany |

|

| KHS GmbH is a respected name in soda filling machine manufacturers, supplying complete beverage filling and packaging lines. Their systems combine sustainability with productivity, ensuring long-term efficiency. The company also provides both high-end and competitive automatic soda filling machine price solutions. |

|

Address: 2980 Scott St, Vista, CA 92081, United States |

|

| Accutek Packaging Equipment provides user-friendly solutions, making them a strong competitor among soda filling machine manufacturers in the U.S. market. Their compact machines suit small-scale beverage operations. They also offer flexible models that align with different soda filling machine price levels. |

|

Address: Via Italia, 43, Gessate Milano, Lombardy, Italy |

|

| Ronchi Mario S.p.A. is a recognized brand among soda gas filling machine manufacturers, designing precision equipment for carbonated beverages. Their systems are compact, reliable, and efficient. Ronchi Mario S.p.A. is also known for providing accessible semi automatic soda filling machine price ranges. |

|

Address: Via G. Garibaldi, 34N, Bonate Sotto, Lombardy, Italy |

|

| Comac is a respected company among rotary soda filling machine manufacturers, delivering highly automated and precise filling systems. Their technology is well-suited for large-scale beverage operations. They also offer machines with a wide span of soda filling machine price options. |

|

Address: Olympus House, Mill Green Road, Haywards Heath, West Sussex, United Kingdom |

|

| Adelphi Packaging Machinery is one of the innovative soda filling machine manufacturers, focusing on advanced automation and modularity. Their soda filling lines are designed for speed and flexibility. They also provide tailored models at competitive automatic soda filling machine price points. |

|

Address: N15 W23500 Stone Ridge Drive, Waukesha, Wisconsin, United States of America |

||

| Federal Mfg.is a trusted supplier among soda filling machine manufacturers. Their filling lines are versatile, supporting both soda and other beverages. They provide scalable systems that suit different semi automatic soda filling machine price expectations. |

|

Address: Hofäckerstraße 9 Crailsheim, Baden-Württemberg, Germany |

|

|

Groninge is one of the well-known soda gas filling machine manufacturers, delivering durable equipment for both large and mid-scale producers. Their focus on long-term efficiency makes them a preferred choice for many soda brands. Groninge also provides systems in line with global soda filling machine price standards. |

|

Address: Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa, Japan |

|

| Shibuya Corporation is one of Asia’s leading soda filling machine manufacturers, known for large-scale beverage production equipment. Their machines are designed for efficiency, durability, and hygiene. Shibuya also provides competitive soda filling machine price offerings for emerging markets. |

|

Address: 15-39 130th St, College Point, New York, United States of America |

|

| Filling Equipment Company is a respected name among soda filling machine manufacturers, offering both automatic and semi-automatic filling systems. Their rotary filling machines are highly efficient and widely used by soda producers. They also provide solutions covering both automatic soda filling machine price and semi automatic soda filling machine price ranges. |

|

Barry-Wehmiller Packaging Systems Address: 8020 Forsyth Boulevard, St. Louis, Missouri, United States of America |

||

| Barry-Wehmiller Packaging Systems is among established soda filling machine manufacturers, offering a broad range of filling equipment. Their designs emphasize precision and adaptability. The company also supports clients with options matching semi automatic soda filling machine price levels. |

|

Address: 1535 South State Road 39, La Porte, IN 46350, United States |

|

| E-PAK Machinery is widely recognized among rotary soda filling machine manufacturers, providing highly efficient filling systems. Their machines are designed to enhance productivity and maintain carbonation stability. E-PAK’s systems also match different automatic soda filling machine price needs. |

Global Distribution of Soda Filling Machine Manufacturers by Country

| Country | Number of Companies | Share (%) |

|

USA | 8 | 40% |

|

Germany | 4 | 20% |

|

China | 3 |

15% |

|

Italy | 2 | 10% |

|

France | 1 | 5% |

|

United Kingdom | 1 | 5% |

|

Japan | 1 | 5% |

List of 16 Soda Filling Machine Products

|

|

An 18-6 soda can filling machine is equipped with 18 filling heads and 6 sealing heads to efficiently fill and seal soda cans in one integrated process. It ensures accurate filling, hygienic operation, and high-speed production, making it ideal for medium to large-scale soda can manufacturing. |

|

|

|

|

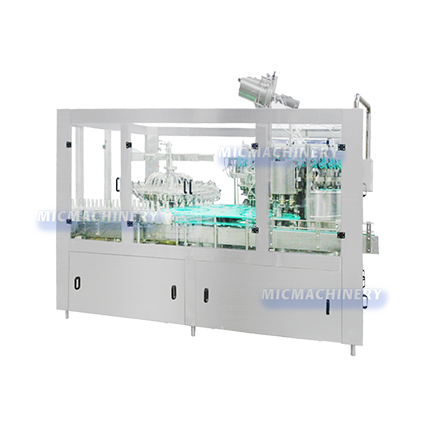

12-12-1 Glass Bottle Soda Filling Machine

A 12-12-1 glass bottle soda filling machine is designed with 12 rinsing heads, 12 filling heads, and 1 capping head to complete bottle rinsing, soda filling, and capping in a single process. It ensures precise filling, hygienic operation, and stable performance, making it ideal for small to medium-scale glass bottle soda production. |

|

|

|

|

18-18-1 Glass Bottle Soda Filling Machine

An 18-18-1 glass bottle soda filling machine is equipped with 18 rinsing heads, 18 filling heads, and 1 capping head to complete bottle rinsing, soda filling, and capping in one integrated process. It ensures accurate filling, hygienic operation, and reliable performance, making it suitable for medium-scale glass bottle soda production. |

|

|

|

|

18-18-6 PET Bottle Soda Filling Machine

An 18-18-6 PET bottle soda filling machine is designed with 18 rinsing heads, 18 filling heads, and 6 capping heads to complete rinsing, filling, and capping of PET bottles in one line. It ensures precise soda filling, hygienic operation, and high efficiency, making it ideal for medium to large-scale PET bottle soda production. |

|

|

|

|

A 24-6 soda can filling machine is equipped with 24 filling heads and 6 sealing heads to efficiently fill and seal soda cans in one process. It ensures accurate dosing, hygienic operation, and high-speed production, making it ideal for large-scale soda can manufacturing. |

|

|

|

|

A 32-8 soda can filling machine comes with 32 filling heads and 8 sealing heads to fill and seal soda cans efficiently in one integrated process. It ensures precise dosing, hygienic operation, and high-speed production, making it ideal for large-scale soda can manufacturing. |

|

|

|

|

40-10 Soda Can Filling Machine

A 40-10 soda can filling machine is equipped with 40 filling heads and 10 sealing heads to efficiently fill and seal soda cans in one process. It ensures accurate dosing, hygienic operation, and high-speed production, making it ideal for large-scale soda can manufacturing. |

|

|

|

|

Small Soda Can Filling Machine

A small soda can filling machine is designed to fill and seal soda cans in smaller production lines. It ensures accurate dosing, hygienic operation, and efficient performance, making it ideal for small to medium-scale soda can manufacturing. |

|

|

|

|

Semi-auto Soda Can Seaming Machine

A semi-auto soda can seaming machine is used to manually place cans while automatically sealing them. It ensures tight, leak-proof seams, hygienic operation, and improved efficiency, making it suitable for small to medium-scale soda can production. |

|

|

|

|

A 12-1 soda can filling machine is equipped with 12 filling heads and 1 sealing head to efficiently fill and seal soda cans in one process. It ensures accurate dosing, hygienic operation, and stable performance, making it ideal for small to medium-scale soda can manufacturing. |

|

|

|

|

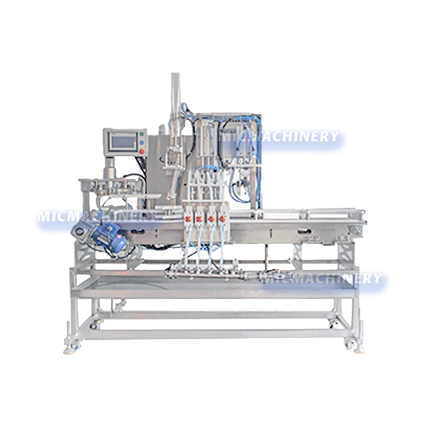

Semi-auto Soda Bottle Filling Machine

A semi-auto soda bottle filling machine is designed to partially automate the filling of soda into bottles. It combines manual handling with automated filling to ensure accurate dosing, hygienic operation, and improved efficiency, making it suitable for small to medium-scale soda production. |

|

|

|

|

Semi-auto Soda Can Filling Machine

A semi-auto soda can filling machine is designed to partially automate the filling of soda into cans. It combines manual operation with automated processes to ensure accurate dosing, hygienic filling, and improved efficiency, making it suitable for small to medium-scale soda can production. |

|

|

|

|

An 18-1 soda can filling machine is equipped with 18 filling heads and 1 sealing head to efficiently fill and seal soda cans in a single process. It ensures accurate dosing, hygienic operation, and stable performance, making it ideal for medium-scale soda can production. |

|

|

|

|

24-24-6 Glass Bottle Soda Filling Machine

A 24-24-6 glass bottle soda filling machine is designed with 24 rinsing heads, 24 filling heads, and 6 capping heads to complete rinsing, filling, and capping in one integrated process. It ensures accurate soda filling, hygienic operation, and high-speed performance, making it ideal for large-scale glass bottle soda production. |

|

|

|

|

18-18-1 Glass Soda Bottling Machine

An 18-18-1 glass soda bottling machine features 18 rinsing heads, 18 filling heads, and 1 capping head to complete rinsing, filling, and capping of glass soda bottles in one line. It ensures precise filling, hygienic operation, and reliable performance, making it ideal for medium-scale soda production. |

|

|

|

|

32-32-8 Glass Bottle Soda Filling Machine

A 32-32-8 glass bottle soda filling machine is equipped with 32 rinsing heads, 32 filling heads, and 8 capping heads to efficiently rinse, fill, and cap glass soda bottles in one integrated process. It ensures high-speed, precise filling, hygienic operation, and reliable performance, making it ideal for large-scale glass bottle soda production. |

|

|