Top 20 Soda Bottle Filling Machine Manufacturers in 2025

Top 20 Soda Bottle Filling Machine Manufacturers in 2025

The crisp fizz of a carbonated soft drink is a sensation engineered not just in the recipe, but in the packaging process. Preserving that carbonation from the mixing tank to the consumer's hand is the singular job of the soda bottle filling machine. For any beverage producer, understanding this technology is key to delivering a consistent, high-quality product. This guide answers the critical questions: how these machines work, what they cost, and how to select the best one for your operation.

How Does a Soda Bottle Filling Machine Work?

A soda bottle filling machine operates on the principle of isobaric counter-pressure filling, a precise process designed to keep dissolved CO₂ in solution. The sequence is as follows:

1. Bottle Rinsing: Empty PET bottles are inverted and purged with jets of clean, filtered air to remove dust and

particulates.

2. Bottle Elevation & Sealing: Bottles are lifted and hermetically sealed against the filling valves on a rotating carousel.

3. Counter-Pressure Cycle: The critical three-step phase begins:

◦ Purging: The sealed bottle is pressurized with CO₂ gas, displacing the oxygen inside to match the pressure in the

liquid product tank.

◦ Filling: The liquid valve opens. Because pressures are equal, the carbonated soda flows smoothly and gently into

the bottle without foaming.

◦ Decompression (Snifting): The liquid valve closes, and the gas pressure in the bottle's headspace is slowly released

in a controlled manner.

4. Bottle Lowering & Capping: The bottle is lowered and immediately conveyed to an integrated capping machine that

applies the closure under pressure, sealing in the fizz.

What is the Cost of a Soda Bottle Filling Machine?

The soda bottle filling machine price varies dramatically based on automation, speed, and scale. It is the single largest cost component within a full soda bottling plant price.

• Semi-Automatic/Small-Scale Lines: Suitable for craft soda or startups, with speeds up to 30 bottles per minute (BPM).

The PET bottle soda filling machine price for such a line can range from $30,000 to $100,000.

• Automatic Mid-Speed Lines: For regional brands, with speeds of 100-400 BPM. A comprehensive machine from

PET bottle soda filling machine manufacturers for this range typically costs between $150,000 and $500,000.

• High-Speed Turnkey Plants: For national production, exceeding 600 BPM. A complete soda bottling plant

price from soda bottling plant machine manufacturers, including mixing, carbonation, and packaging, can start at $1

million and exceed $5 million.

Which Soda Bottle Filling Machine is Best?

The "best" machine is the one that optimally matches your specific business needs. Key selection criteria include:

• Required Production Output (Bottles Per Hour): This is the primary driver. Overbuying wastes capital; underbuying

limits growth.

• Level of Automation: Balance higher upfront cost against long-term labor savings and consistency.

• Bottle Size Range & Compatibility: Ensure the machine can handle your current and planned bottle formats.

• Manufacturer Support & Reputation: The best technical support is as valuable as the machine itself. Partner with

established soda bottling plant machine manufacturers known for reliability and service.

• Integration with Downstream Equipment: The filler must sync perfectly with the

soda bottle packing machine manufacturers' equipment for casing and palletizing.

Filling Technology and Mechanisms

The core mechanism is the counter-pressure filling valve. These sophisticated valves have separate internal channels for gas and liquid, allowing for the precise sequence of purging, filling, and snifting. Modern machines use electronic controls to manage pressures, temperatures, and fill heights with extreme accuracy, ensuring every bottle has the perfect level of carbonation.

Advantages and Benefits of Filling Machines

Investing in a dedicated soda filler delivers undeniable competitive advantages:

• Carbonation Preservation: Expertly manages pressure to ensure the signature "fizz" is perfectly maintained in every

bottle.

• High-Speed, High-Efficiency Production: Enables the large-scale output necessary for market competition.

• Minimized Product Waste: Precision filling drastically reduces costly overfilling and spillage of product.

• Enhanced Hygiene & Safety: Constructed from food-grade stainless steel with CIP (Clean-in-Place) systems, meeting

strict sanitary standards.

• Brand Consistency: Guarantees uniform fill levels, carbonation, and professional presentation that builds consumer

trust.

Troubleshooting and Maintenance Considerations

Proactive maintenance is critical for a product as sensitive as carbonated soda. Common issues include:

• Excessive Foaming: Caused by warm product temperature, low CO₂ pressure in the product tank, or worn/dirty filling

valve seals.

• Low Carbonation (Flat Product): Results from leaks in the CO₂ purging system, incorrect pressure settings, or faulty

valves.

• Inconsistent Fill Levels: Often due to clogged liquid nozzles, fluctuating product tank pressure, or faulty level sensors.

A rigorous preventive maintenance schedule is non-negotiable. This includes daily CIP cycles, weekly inspection and replacement of valve O-rings and seals, and regular calibration of pressure gauges and fill height sensors. This diligent upkeep protects your significant investment, whether considering the standalone soda bottle filling machine price or the total soda bottling plant price, and ensures uninterrupted production of a quality product.

List of 20 Soda Bottle Filling Machine Manufacturers

|

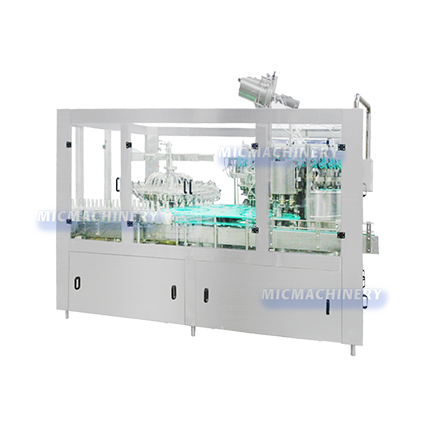

Address: Room 1905, Youyi Building, Xincheng Avenue, Cixi, Ningbo, Zhejiang, China |

|

| Mic Machinery is a global leader in PET bottle soda filling machine manufacturers, providing high-precision filling solutions for carbonated beverages. Their lines ensure accurate fill levels while maintaining carbonation. They offer complete systems with capping, labeling, and packaging. Customers benefit from worldwide installation and after-sales support. |

|

Address: 152 Longquan Bay, Xueyan Town, Wujin, Changzhou, Jiangsu, China |

|

| BW Filling Machinery offers high-speed PET soda filling solutions suitable for medium to large plants. Their machines reduce product loss and foam formation, ensuring consistent beverage quality. The company provides competitive PET bottle soda filling machine price for budget planning. Technical support and maintenance services are included. |

|

Address: 2224 Wukesong Road, Sanxing town, Zhangjiagang, Jiangsu, China |

|

| Zhangjiagang Mic Machinery manufactures automated soda bottling systems that maintain carbonation and reduce wastage. Their equipment integrates filling, capping, and labeling in one line. Flexible configurations accommodate different PET bottle sizes. Customers can access soda bottle filling machine price for planning purposes. |

|

Address: Böhmerwaldstraße 5, 93073 Neutraubling, Bavaria, Germany |

|

| Krones produces fully automated soda lines for industrial operations, combining hygiene, speed, and energy efficiency. Their systems include capping, labeling, and inspection units. The company provides consulting services for optimizing beverage production. Krones is widely used in large-scale soda plants and known as a soda bottling plant machine manufacturer. |

|

Address: 1535 S State Road 39, La Porte, Indiana, United States of America |

|

| APACKS offers compact and efficient soda filling machines for small- to medium-sized plants. Their systems ensure minimal foam formation and precise fill levels. Customers can access soda bottling plant price for cost estimation. APACKS also provides installation, training, and technical support. |

|

Address: Avenue de la Patrouille de France, 76930 Octeville-sur-Mer, Normandy, France |

|

| Sidel delivers automated PET soda filling lines with integrated capping and labeling. Their equipment emphasizes hygiene and operational efficiency. The company provides solutions for various bottle sizes. Global installation and support are included. |

|

Address: 50 Schoolhouse Road Somerset, New Jersey, United States of America |

|

| Cozzoli manufactures modular soda filling machines suitable for industrial and mid-scale producers. Their lines minimize product loss while maintaining beverage quality. Cozzoli also offers installation and training services. Automation and precise carbonation control are key features. |

|

Address: Stuttgarter Straße 130, Waiblingen, Baden-Württemberg, Germany |

||

| Syntegon specializes in high-speed PET soda filling lines that reduce foam and wastage. Their systems include capping, labeling, and inspection for complete turnkey solutions. Syntegon provides global installation and maintenance support. Their equipment maintains carbonation and production efficiency. |

|

Address: 4119 Fordleigh Road Baltimore, Maryland, United States of America |

||

| Filamatic offers reliable soda bottling machines for mid- to large-scale operations. Their systems ensure accurate filling while maintaining beverage quality. The company provides full installation and technical support. Filamatic machines handle a wide range of PET bottle sizes. |

|

Address: Juchostrasse 20, 44143 Dortmund, Germany |

|

| KHS GmbH provides automated soda filling systems for industrial-scale plants. Their lines ensure precise fill levels and minimal foam formation. The company also delivers soda bottle packing machine manufacturers solutions for capping, labeling, and packaging. Installation, training, and support services are included globally. |

|

Address: 2980 Scott St, Vista, CA 92081, United States |

|

| Accutek produces flexible PET soda filling lines suitable for small- and medium-scale plants. Their equipment emphasizes efficiency and accurate carbonation retention. The company offers installation, training, and maintenance services. Accutek machines accommodate different PET bottle formats. |

|

Address: Via Italia, 43, Gessate Milano, Lombardy, Italy |

|

| Ronchi Mario provides fully automated soda filling systems for industrial operations. Their machines maintain precise fill levels and reduce beverage wastage. The company also offers capping, labeling, and turnkey solutions. Global installation and maintenance support are included. |

|

Address: Via G. Garibaldi, 34N, Bonate Sotto, Lombardy, Italy |

|

| Comacdesigns versatile PET soda bottling systems that focus on hygiene and operational efficiency. Their lines minimize foam and wastage while maintaining carbonation. The company provides installation, training, and technical support services. Comac systems are compatible with different PET bottle sizes. |

|

Address: Olympus House, Mill Green Road, Haywards Heath, West Sussex, United Kingdom |

|

| Adelphi supplies compact and efficient soda filling machines for small- to medium-scale plants. Their systems ensure accurate filling and consistent beverage quality. The company provides turnkey solutions including capping and labeling. Installation and technical support are included. |

|

Address: N15 W23500 Stone Ridge Drive, Waukesha, Wisconsin, United States of America |

||

| Federal Mfg. produces high-speed PET soda filling lines that reduce foam and maintain carbonation. Their machines are suitable for small and large operations. The company offers full installation and support services. Federal Mfg. equipment is widely recognized for reliability. |

|

Address: Hofäckerstraße 9 Crailsheim, Baden-Württemberg, Germany |

|

|

Groninge manufactures automated soda filling machines for mid- and large-scale plants. Their systems ensure precise filling and minimal product loss. They also provide global installation and maintenance services. Equipment is suitable for a wide range of PET bottles. |

|

Address: Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa, Japan |

|

| Shibuya provides compact and precise soda filling machines for industrial and small-scale plants. Their systems maintain carbonation and minimize waste. Shibuya offers installation and training services. Equipment is compatible with various PET bottle formats. |

|

Address: 15-39 130th St, College Point, New York, United States of America |

|

| Filling Equipment Company produces automated soda filling lines with accurate fill control. Their machines ensure minimal foam and product loss. They offer complete turnkey solutions including capping and labeling. Installation, training, and after-sales support are included. |

|

Barry-Wehmiller Packaging Systems Address: 8020 Forsyth Boulevard, St. Louis, Missouri, United States of America |

||

| Barry-Wehmiller delivers industrial PET soda bottling lines with high-speed filling. Their machines maintain carbonation and ensure consistent fill levels. Turnkey solutions with installation and training are included. The company is recognized for durable and precise equipment. |

|

Address: 1535 South State Road 39, La Porte, IN 46350, United States |

|

| E-PAK provides small- to medium-scale PET soda bottling systems with accurate filling and minimal foam formation. Their machines are easy to operate and maintain. Installation, training, and technical support are included. Equipment can handle multiple PET bottle sizes efficiently. |

Global Distribution of Soda Bottle Filling Machine Manufacturers by Country

| Country | Number of Companies | Share (%) |

|

USA | 8 | 40% |

|

Germany | 4 | 20% |

|

China | 3 |

15% |

|

Italy | 2 | 10% |

|

France | 1 | 5% |

|

United Kingdom | 1 | 5% |

|

Japan | 1 | 5% |

List of 7 Soda Bottle Filling Machine Products

|

|

18-18-6 PET Bottle Soda Filling Machine

An 18-18-6 PET bottle soda filling machine is equipped with 18 rinsing heads, 18 filling heads, and 6 capping heads to complete rinsing, filling, and capping in one line. It ensures precise soda filling, hygienic operation, and high efficiency, making it ideal for medium to large-scale soda production. |

|

|

|

|

24-24-6 Glass Bottle Soda Filling Machine

A 24-24-6 glass bottle soda filling machine features 24 rinsing heads, 24 filling heads, and 6 capping heads to handle rinsing, filling, and capping in one integrated system. It ensures accurate soda filling, safe and hygienic operation, and high-speed performance, making it ideal for large-scale glass bottle soda production. |

|

|

|

|

18-18-1 Glass Bottle Soda Filling Machine

An 18-18-1 glass bottle soda filling machine is designed with 18 rinsing heads, 18 filling heads, and 1 capping head to complete bottle cleaning, soda filling, and capping in one process. It ensures accurate filling, hygienic operation, and stable performance, making it suitable for medium-scale glass bottle soda production. |

|

|

|

|

12-12-1 Glass Bottle Soda Filling Machine

A 12-12-1 glass bottle soda filling machine comes with 12 rinsing heads, 12 filling heads, and 1 capping head to complete rinsing, filling, and capping in a single line. It ensures precise soda filling, hygienic processing, and reliable performance, making it ideal for small to medium-scale glass bottle soda production. |

|

|

|

|

Semi-auto Soda Bottling Machine

A semi-auto soda bottling machine is designed to partially automate the rinsing, filling, and capping of soda bottles. It combines manual operation with automated processes to ensure accurate filling, hygienic packaging, and improved efficiency, making it suitable for small to medium-scale soda production. |

|

|

|

|

18-18-1 Glass Soda Bottling Machine

An 18-18-1 glass soda bottling machine is designed with 18 rinsing heads, 18 filling heads, and 1 capping head to efficiently rinse, fill, and cap glass soda bottles in one line. It ensures accurate filling, hygienic operation, and stable performance, making it ideal for medium-scale soda production. |

|

|

|

|

32-32-8 Glass Bottle Soda Filling Machine

A 32-32-8 glass bottle soda filling machine is equipped with 32 rinsing heads, 32 filling heads, and 8 capping heads to efficiently rinse, fill, and cap glass bottles in one integrated system. It ensures high-speed, precise soda filling, hygienic operation, and reliable performance, making it ideal for large-scale glass bottle soda production. |

|

|