Top 20 Juice Filling and Sealing Machine Manufacturers in 2025

Top 20 Juice Filling and Sealing Machine Manufacturers in 2025

For juice producers, the final step of transforming liquid into a shelf-ready product is critical. The equipment that accomplishes this—the juice filling and sealing machine—must ensure product integrity, hygiene, and efficiency. Choosing the right system can define a brand's quality and scalability. This guide answers key questions about these integrated machines: what types exist, how they operate, and how to select the perfect one for your operation.

What are the Different Types of Juice Filling and Sealing Machines?

These machines are categorized by their automation level, container type, and sealing method. The primary types include:

• Semi-Automatic Fillers: Require manual bottle placement and cap feeding but automate the fill and capping cycle. Ideal

for startups and low-volume producers, these are the focus of many small juice filling machine manufacturers.

• Automatic In-Line Fillers: Bottles are conveyed automatically under a series of filling valves, then to an integrated

capper. These mid-speed systems are a common offering from juice bottle filling machine manufacturers.

• Automatic Rotary Fillers: The high-speed standard for large volumes. Bottles travel around a circular carousel for

simultaneous filling and capping in a continuous motion, engineered by leading

automatic juice filling machine manufacturers.

• Pouch Fillers (Form-Fill-Seal): Create the pouch from a roll of film, fill it with juice, and seal it in one integrated process.

This is a specialized segment within the broader field of juice filling and sealing machine manufacturers.

How Does a Juice Filling and Sealing Machine Work?

The process is a seamless, integrated sequence designed to minimize contamination and maximize speed:

1. Bottle Feeding & Cleaning: Bottles are fed onto the conveyor and typically inverted for an air or water rinse.

2. Filling: Bottles enter the filling section. For most juices—especially pulpy varieties—volumetric piston filling is used. A

piston draws a precise volume from a hopper and dispenses it into the bottle.

3. Immediate Sealing/Capping: The filled bottle is instantly transferred to the sealing section. For bottles, this is a capping

head that applies and tightens screw caps or press-on lids. This integrated step is why

juice filling and capping machine manufacturers design both functions to work in perfect synchronization.

4. Discharge & Labeling: The sealed bottle is conveyed out for labeling, coding, and packaging.

How to Choose a Juice Filling and Sealing Machine?

Selecting the right machine requires careful evaluation of several factors:

• Production Volume: Determine your required output (bottles per hour). This is the biggest driver in choosing between

semi-automatic, in-line, or rotary systems.

• Juice Characteristics: Consider pulp content, viscosity, and whether the juice is cold-filled, hot-filled (for shelf stability),

or aseptic. Pulpy juices demand robust piston fillers.

• Container Type & Size: Specify if you use glass or PET bottles, and the range of sizes. Machines need compatible

handling systems.

• Budget: Balance upfront cost with long-term efficiency. A lower-cost semi-automatic machine has higher labor costs per

bottle.

• Future Growth: Choose a machine that can scale with your business or allows for easy upgrades.

• Manufacturer Reputation: Partner with reputable juice filling and sealing machine manufacturers known for reliability,

service support, and supply of genuine spare parts.

Filling Technology and Mechanisms

The dominant technology for juice is positive displacement piston filling. Its mechanism ensures accuracy regardless of product viscosity:

• A piston retracts within a sealed cylinder, drawing a set volume of juice.

• The bottle is raised to seal against the nozzle.

• The piston advances, cleanly pushing the exact juice volume into the container.

• For hot-fill applications, the entire product path is heated to maintain temperature.

Advantages and Benefits of Filling and Sealing Machines

Investing in an integrated system offers transformative advantages:

• Extended Shelf Life: Minimizes exposure time between filling and sealing, reducing oxidation risk. Hot-fill capabilities

create a preservative-free shelf-stable product.

• Superior Hygiene: An enclosed, automated process drastically reduces the risk of contamination compared to manual

handling.

• High Operational Efficiency: Combines two critical steps into one streamlined process, saving space, time, and labor

costs.

• Exceptional Accuracy: Volumetric filling ensures consistent fill levels, complying with regulations and eliminating

product giveaway.

• Professional Quality & Consistency: Delivers a reliably sealed, leak-free product that builds brand trust.

Troubleshooting and Maintenance Considerations

Juice's sugar and acid content demands rigorous maintenance to prevent stickiness and microbial growth.

• Inaccurate Fills: Often caused by pulp clogging valves, worn piston seals, or air in the product line.

• Poor Seal Integrity: Can result from misaligned capping heads, incorrect cap torque settings, or contaminated bottle

necks.

• Leakage or Dripping: Check for worn nozzle O-rings, damaged valve seats, or residual pulp preventing a clean seal.

A strict preventive maintenance schedule is non-negotiable:

• Daily: Complete disassembly, cleaning, and sanitization of all product-contact parts (pistons, cylinders, nozzles,

capping heads).

• Weekly: Inspection and replacement of seals and gaskets. Lubrication of moving parts with food-grade lubricant.

• Monthly: Calibration of fill volumes and capper torque settings.

Proactive care, guided by manuals from your juice filling and capping machine manufacturers, protects your investment and ensures the consistent quality that consumers expect from your juice.

List of 20 Juice Filling and Sealing Machine Manufacturers

|

Address: Room 1905, Youyi Building, Xincheng Avenue, Cixi, Ningbo, Zhejiang, China |

|

| Mic Machinery is recognized among juice filling and sealing machine manufacturers for providing reliable solutions for bottled juice production. The company designs equipment with stable filling accuracy and consistent sealing performance. Its machines support multiple bottle formats and production capacities. Mic Machinery serves juice producers seeking long-term operational efficiency. |

|

Address: 152 Longquan Bay, Xueyan Town, Wujin, Changzhou, Jiangsu, China |

|

| BW Filling Machinery specializes in intelligent beverage filling technology. Its equipment is designed for automated juice bottling and sealing processes. The company emphasizes digital control and production stability. BW Filling Machinery machines are exported to international beverage markets. |

|

Address: 2224 Wukesong Road, Sanxing town, Zhangjiagang, Jiangsu, China |

|

| Zhangjiagang Mic Machinery provides turnkey juice filling and packaging solutions. The company focuses on consistent machine performance and reduced downtime. Its systems support complete juice production lines. Zhangjiagang Mic Machinery serves global beverage manufacturers. |

|

Address: Böhmerwaldstraße 5, 93073 Neutraubling, Bavaria, Germany |

|

| Krones AG is a global leader in beverage filling and packaging technology. The company supplies advanced systems widely used by juice bottle filling machine manufacturers worldwide. Its equipment integrates filling, sealing, and line automation. Krones solutions are commonly adopted by large-scale beverage plants. |

|

Address: 1535 S State Road 39, La Porte, Indiana, United States of America |

|

| APACKS supplies food and beverage processing and packaging equipment. Its juice filling systems prioritize hygiene and precision. The company offers customized engineering based on product requirements. APACKS machines are trusted by multinational juice producers. |

|

Address: Avenue de la Patrouille de France, 76930 Octeville-sur-Mer, Normandy, France |

|

| Sidel develops high-performance filling and sealing systems for PET and glass bottles. The company is active among automatic juice filling machine manufacturers serving modern beverage factories. Its machines emphasize hygienic design and energy efficiency. Sidel equipment supports high-speed juice bottling operations. |

|

Address: 50 Schoolhouse Road Somerset, New Jersey, United States of America |

|

| Cozzoli Machine Company is known for integrated filling and sealing systems for liquid foods. The company focuses on product safety and shelf-life optimization. Its juice equipment supports high-volume production. Cozzoli solutions are widely used worldwide. |

|

Address: Stuttgarter Straße 130, Waiblingen, Baden-Württemberg, Germany |

||

| Syntegon Technology GmbH delivers advanced packaging solutions for liquid foods. Its machines are commonly supplied by juice filling and capping machine manufacturers serving regulated markets. The company focuses on automation and process reliability. Syntegon equipment supports diverse bottle formats. |

|

Address: 4119 Fordleigh Road Baltimore, Maryland, United States of America |

||

| Filamatic manufactures packaging machinery for liquid and semi-liquid products. Its juice filling systems emphasize accuracy and sealing stability. The company supports flexible packaging configurations. Filamatic machines are widely used in developing markets. |

|

Address: Juchostrasse 20, 44143 Dortmund, Germany |

|

| KHS Group produces filling and sealing machinery for liquid food applications. Its juice solutions focus on robust construction and easy maintenance. The company supports modular production line configurations. KHS equipment is widely installed in industrial juice facilities. |

|

Address: 2980 Scott St, Vista, CA 92081, United States |

|

| Accutek Packaging Equipment specializes in compact filling and sealing machines. Its juice equipment is suitable for mid-scale beverage operations. The company focuses on ease of operation and quick changeovers. Accutek machines are used by growing juice brands. |

|

Address: Via Italia, 43, Gessate Milano, Lombardy, Italy |

|

| Ronchi Mario S.p.A. provides flexible packaging solutions for liquid products. Its juice machines support automated filling and sealing processes. The company emphasizes modular design. Ronchi equipment is widely used in pouch-based juice packaging. |

|

Address: Via G. Garibaldi, 34N, Bonate Sotto, Lombardy, Italy |

|

| Comac designs filling and sealing machines for liquid foods. The company is active among small juice filling machine manufacturers serving startups and regional producers. Its machines focus on operational simplicity. Comac equipment is suitable for limited production spaces. |

|

Address: Olympus House, Mill Green Road, Haywards Heath, West Sussex, United Kingdom |

|

| Adelphi Packaging Machinery supplies precision filling systems for beverage applications. Its juice machines are engineered for durability and accuracy. The company supports customized project requirements. Adelphi equipment serves multiple food industries. |

|

Address: N15 W23500 Stone Ridge Drive, Waukesha, Wisconsin, United States of America |

||

| Federal Mfg. manufactures filling and sealing machinery for liquids. Its juice equipment emphasizes hygienic construction and efficient throughput. The company supports both standalone and integrated systems. Federal machines are used in European beverage plants. |

|

Address: Hofäckerstraße 9 Crailsheim, Baden-Württemberg, Germany |

|

|

Groninge produces filling and sealing equipment for liquid products. Its juice machines focus on cost-effective automation solutions. The company supports flexible production needs. Groninge equipment serves competitive juice markets. |

|

Address: Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa, Japan |

|

| Shibuya Corporation specializes in rotary pouch filling and sealing machines. Its juice equipment provides accurate dosing and stable sealing. The company focuses on automated packaging technology. Shibuya machines are widely installed in Asia. |

|

Address: 15-39 130th St, College Point, New York, United States of America |

|

| Filling Equipment Company supplies filling and sealing machinery for bottles and pouches. Its juice solutions support flexible automation levels. The company focuses on machine longevity. Filling Equipment Company serves medium-sized beverage manufacturers. |

|

Barry-Wehmiller Packaging Systems Address: 8020 Forsyth Boulevard, St. Louis, Missouri, United States of America |

||

| Barry-Wehmiller Packaging Systems designs advanced packaging solutions for liquid foods. Its juice filling systems support high-speed pouch packaging. The company emphasizes innovation and digitalization. Barry-Wehmiller equipment is used by premium beverage brands. |

|

Address: 1535 South State Road 39, La Porte, IN 46350, United States |

|

| E-PAK Machinery manufactures filling and sealing machinery for liquid food applications. Its portfolio aligns with juice bottle filling machine manufacturers targeting small and medium producers. The company emphasizes durability and cost efficiency. E-PAK equipment supports growing juice businesses. |

Global Distribution of Juice Filling and Sealing Machine Manufacturers by Country

| Country | Number of Companies | Share (%) |

|

USA | 8 | 40% |

|

Germany | 4 | 20% |

|

China | 3 |

15% |

|

Italy | 2 | 10% |

|

France | 1 | 5% |

|

United Kingdom | 1 | 5% |

|

Japan | 1 | 5% |

List of 8 Juice Filling and Sealing Machine Products

|

|

12-1 Juice Can Filling Machine

A 12-1 juice can filling machine is designed with 12 filling heads and 1 sealing head to efficiently fill juice into cans and seal them in a single process. It ensures accurate dosing, hygienic operation, and stable performance, making it suitable for medium to large-scale juice production. |

|

|

|

|

18-6 Juice Can Filling Machine

An 18-6 juice can filling machine is equipped with 18 filling heads and 6 sealing heads to handle juice canning with high speed and precision. It ensures accurate filling, reliable sealing, and hygienic operation, making it ideal for large-scale juice production lines. |

|

|

|

|

18-18-6 Juice Bottle Filling Machine

An 18-18-6 juice bottle filling machine is designed with 18 rinsing heads, 18 filling heads, and 6 capping heads to complete bottle rinsing, juice filling, and capping in one integrated process. It ensures accurate filling, hygienic operation, and high efficiency, making it ideal for medium to large-scale juice production. |

|

|

|

|

A juice cup filling machine is designed to fill and seal juice into cups quickly and hygienically. It ensures accurate filling, secure sealing, and efficient production, making it ideal for beverage companies producing ready-to-drink juice cups. |

|

|

|

|

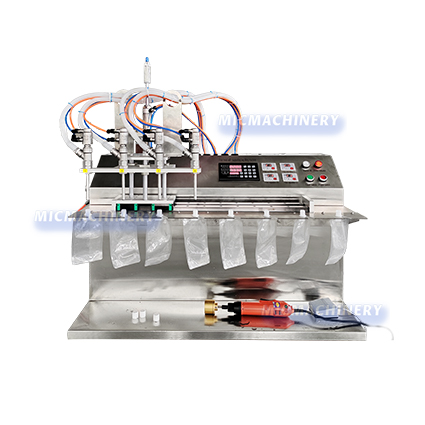

Juice Spout Pouch Filling Machine

A juice spout pouch filling machine is designed to fill juice into spouted pouches with precision and efficiency. It ensures accurate dosing, hygienic operation, and reliable sealing, making it ideal for beverage manufacturers producing convenient, ready-to-drink juice packaging. |

|

|

|

|

A juice pouch packing machine is used to efficiently fill and seal juice into flexible pouches. It ensures accurate filling, hygienic packaging, and smooth operation, making it ideal for beverage manufacturers producing convenient, ready-to-drink juice pouches. |

|

|

|

|

Juice Spout Pouch Packing Machine

A juice spout pouch packing machine is designed to fill and seal juice into spouted pouches in a clean and efficient process. It ensures precise filling, secure sealing, and hygienic packaging, making it ideal for beverage manufacturers focused on convenient juice pouch production. |

|

|

|

|

Semi-auto Juice Spout Pouch Filling Machine

A semi-auto juice spout pouch filling machine is used to fill juice into spouted pouches with partial automation. It combines manual handling with automated filling to ensure accurate dosing, hygienic packaging, and cost-effective production, making it suitable for small to medium-scale juice manufacturers. |

|

|