Top 20 Hand Sanitizer Filling Machine Factories in 2025

Top 20 Hand Sanitizer Filling Machine Factories in 2025

The demand for hand sanitizers has surged worldwide, making efficient and hygienic packaging solutions essential for manufacturers. Whether producing alcohol-based gels or liquid disinfectants, companies rely on automated systems to maintain safety, accuracy, and high output. To better understand the technology, this article begins by answering four key questions:

What Are the Machines Used for Hand Sanitizer Production?

What Is a Hand Sanitizer Filling Machine?

What Are the Different Types of Hand Sanitizer Filling Machines?

What Is the Principle of Automatic Hand Sanitizer Filling Machine?

List of 20 Hand Sanitizer Filling Machine Factories

Let’s explore the answers while introducing how a professional hand sanitizer filling machine factory plays a vital role in ensuring product quality and packaging efficiency.

What Are the Machines Used for Hand Sanitizer Production?

Hand sanitizer production involves multiple stages and specialized equipment to ensure purity, consistency, and contamination-free packaging. Key machines include:

• Mixing and Blending Tanks: Used to combine ingredients such as alcohol, water, glycerin, and essential oils.

• Emulsifiers and Homogenizers: Ensure uniform consistency, especially for gel-type formulas.

• Storage Tanks: Temporarily hold the product before filling.

• Filling Machines: Accurately dispense the sanitizer into bottles or containers.

• Capping Machines: Seal containers tightly to prevent leakage and contamination.

• Labeling Machines: Apply branding and safety information.

Each piece of equipment is typically integrated into a full hand sanitizer filling line factory setup that meets GMP and hygiene standards. Efficient layout planning and automation are essential for maintaining production speed and reducing labor dependency.

What Is a Hand Sanitizer Filling Machine?

A hand sanitizer filling machine is designed to fill containers with alcohol-based liquid or gel sanitizer accurately and safely. Whether filling 50ml bottles or large 1-liter containers, these machines ensure the correct volume is dispensed with minimal spillage or air bubbles.

Depending on the formula's viscosity, a filling machine for hand sanitizer factory may supply either piston fillers, peristaltic pump fillers, or gravity-fed systems. These machines must be corrosion-resistant and compatible with flammable substances, often requiring explosion-proof configurations.

A high-quality hand sanitizer filling machine factory provides machines that meet international standards for hygiene and reliability, often integrating them into turnkey filling lines.

What Are the Different Types of Hand Sanitizer Filling Machines?

There are several types of filling machines used to handle the different textures and packaging requirements of hand sanitizers. Here’s an overview:

a. Gravity Fillers

• Suitable for thin, alcohol-based liquid sanitizers

• Operate using gravity to dispense product into bottles

• Low-cost option for low to medium production

b. Piston Fillers

• Ideal for gel-type sanitizers

• Uses a piston to pull and push product into containers

• Highly accurate and suitable for thicker viscosities

• Commonly produced by specialized gel sanitizer filling machine factory setups

c. Peristaltic Pump Fillers

• Best for cleanroom applications and small volume fills

• Liquid only contacts food-grade tubing, preventing cross-contamination

• Used by high-precision hand sanitiser filling machine factory suppliers

d. Overflow Fillers

• Offers consistent fill levels in clear containers

• Suited for liquid sanitizers packaged in display bottles

e. Manual & Semi-Automatic Fillers

• Ideal for small-scale producers

• Cost-effective for startups or low-volume filling

Advanced models, especially from an automatic hand sanitizer bottle filling machine factory, may include integrated bottle feeding, filling, capping, and labeling to streamline operations.

What Is the Principle of Automatic Hand Sanitizer Filling Machine?

An automatic hand sanitizer filling machine operates based on precision dosing and contactless dispensing, controlled by programmable logic controllers (PLC). Here’s how it works:

1. Bottle Feeding: Bottles are automatically aligned on a conveyor belt.

2. Filling: Nozzles lower into the containers and fill them using a pre-set volume. For gels, piston-based pumps push the product with strong force; for liquids, gravity or pump systems are used.

3. Capping: Caps are placed and tightened using torque-controlled systems.

4. Sealing & Labeling: Optional induction sealers and labeling heads apply necessary finishing touches.

5. Discharge: Finished bottles exit the system, ready for secondary packaging.

A reliable sanitizing gel filling machine factory ensures this entire process is seamless, safe, and easy to clean—crucial when handling alcohol-based formulas.

List of 20 Hand Sanitizer Filling Machine Factories

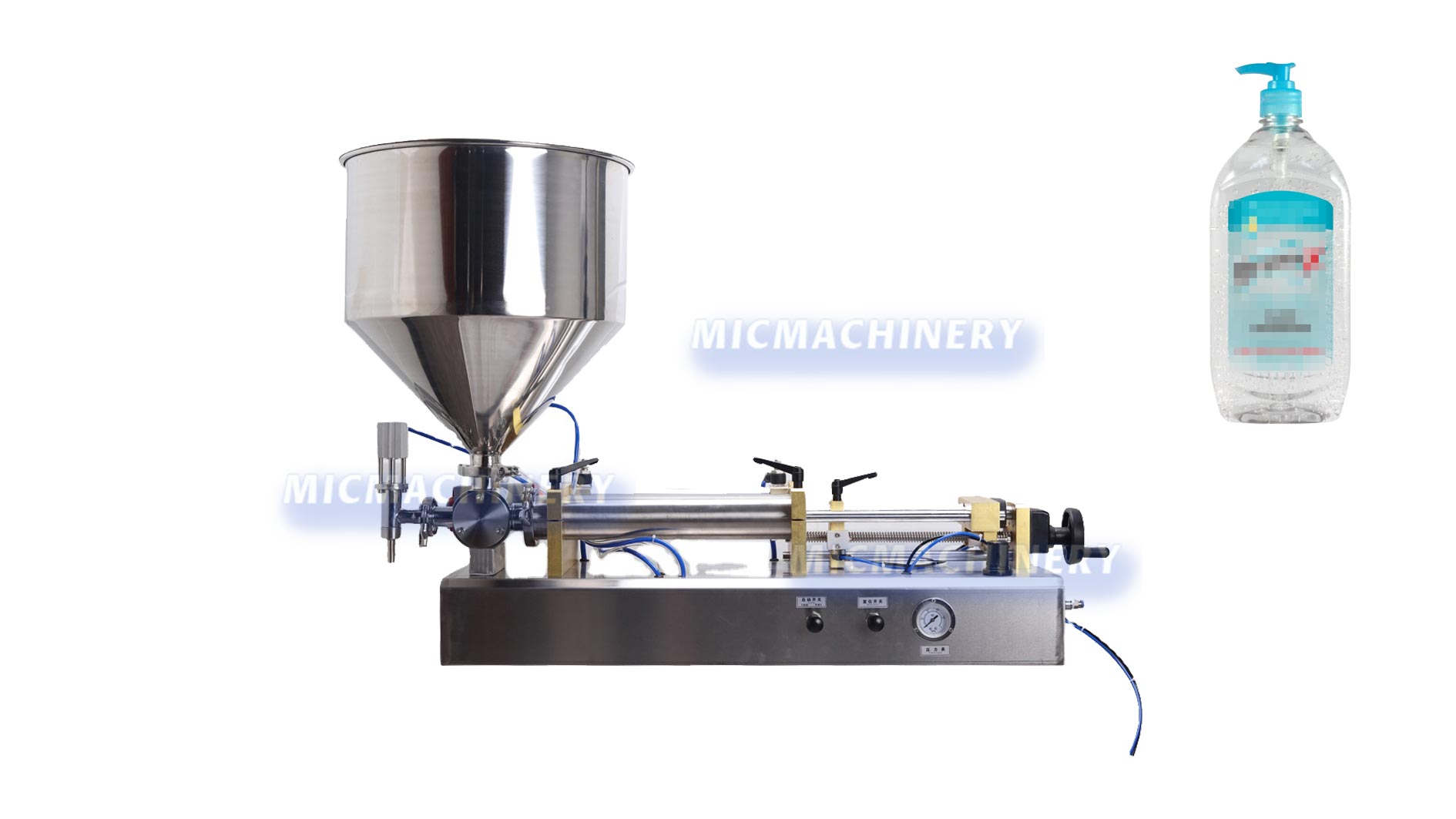

Mic Machinery is a leading hand sanitizer filling machine factory based in China, known for its fully automatic and semi-automatic solutions. They offer turnkey options from filling to capping and labeling, ensuring high accuracy even with thick gels. As a professional filling machine for hand sanitizer factory, Mic Machinery provides flexible configurations to suit both startups and large-scale manufacturers.

Powering Machinery, located in the China, is a trusted gel sanitizer filling machine factory offering piston, peristaltic, and overflow systems. They serve both large pharmaceutical companies and small cosmetic firms. Their robust machines make them a preferred hand sanitizer bottle filling machine factory in North America.

3. Zhangjiagang Mic Machinery (China) ![]()

Zhangjiagang Mic Machinery is a Chinese-based hand sanitiser filling machine factory that offers a complete liquid packaging line for sanitizers. Their machines are compatible with various container types and fill volumes. Known for being an affordable and scalable hand sanitizer filling line factory, Zhangjiagang Mic Machinery supports international OEM clients.

Krones AG is a German-based hand sanitizer filling machine factory offering time-based and volumetric fillers tailored for viscous liquids. Their machines are widely used in the personal care and pharmaceutical sectors. With in-house engineering support, they also function as a full-service hand sanitizer packaging machine factory.

Scholle IPN offers semi and fully automated systems as a top-tier filling machine for hand sanitizer factory in the U.S. Their piston and peristaltic fillers are ideal for thick gels, including alcohol-based formulations. They are also respected as a sanitizing gel filling machine factory serving hospitals and medical supply chains.

Tetra Pak is a Swedish-based hand sanitizer filling line factory offering net weight filling systems for maximum accuracy. Their machinery is designed for high-output operations in the cosmetic and healthcare industries. As a premium sanitizer bottling machine factory, Tetra Pak’R integrates advanced capping and rinsing modules.

Sidel, headquartered in France, is a renowned hand sanitizer packaging machine factory known for its rotary piston filling technology. Their machines are customizable for viscosity levels and bottle sizes. Sidel's long-standing expertise also makes them a high-performance hand sanitizer filling machine factory.

Pattyn Group is a Belgian gel sanitizer filling machine factory known for offering entry-level to industrial-grade solutions. They provide inline filling systems that are easy to clean and integrate with cap sorters and conveyors. Their presence as a hand sanitizer packaging machine factory is growing rapidly across Asia and Africa.

Gebo Cermex is a global filling machine for hand sanitizer factory that provides rotary net weight fillers with high-speed automation. Their hygienic designs make them a preferred vendor in medical and food-grade applications. Gebo Cermex also manufactures full lines as a modern hand sanitizer filling line factory.

KHS GmbH, based in Germany, is a compact hand sanitiser filling machine factory offering tabletop piston fillers for gel and alcohol-based sanitizers. Their solutions are widely used by artisans and small-scale brands. Despite its size, KHS GmbH is also a reputable sanitizing gel filling machine factory in Europe.

11. Accutek Packaging Equipment (USA) ![]()

Accutek is a American hand sanitizer bottle filling machine factory offering cost-effective solutions for both automatic and manual lines. They provide capping and labeling integration for turnkey packaging. Their modular approach supports both local and international clients.

12. Ronchi Mario S.p.A. (Italy) ![]()

Ronchi Mario is a respected Italy hand sanitizer filling machine factory providing customizable liquid fillers designed for thick substances. Their inline systems are commonly used in industrial hand cleaner and gel product packaging. They also provide conveyors, accumulators, and cappers.

13. Comac (Italy) ![]()

Comac is a Italian-based sanitizer bottling machine factory offering precision-engineered liquid filling systems. Their servo-driven platforms ensure consistency at high production speeds. They're often selected by multinational pharmaceutical companies.

14. Adelphi Packaging Machinery (UK) ![]()

Adelphi, from UK, is a versatile hand sanitizer packaging machine factory that produces gravity and piston fillers. Their machines are affordable, scalable, and built for durability. The company is rapidly gaining reputation as a reliable filling machine for hand sanitizer factory.

Federal Mfg. is a U.S.-based gel sanitizer filling machine factory offering custom-built machines with multiple filling heads. Their systems accommodate low-viscosity liquids and thick gels, with overflow and gravity filling options. IFS also supports contract packagers and OEMs.

AVE Technologies, a Italian-based hand sanitizer filling line factory, offers complete filling, capping, and labeling equipment with CE certification. Their piston fillers are suited for disinfectants, gels, and lotions. AVE Technologies is also active as a hand sanitizer packaging machine factory across Europe.

17. Shibuya Corporation (Japan) ![]()

Shibuya Corporation is a dependable hand sanitizer filling machine factory in the Japan with a reputation for affordable inline filling machines. Their servo-controlled systems offer excellent accuracy for thick and thin liquids. Their machines are often seen in both small and mid-scale production facilities.

18. Aseptic Technologies (Belgium) ![]()

Aseptic Technologies is a rising Chinese hand sanitiser filling machine factory focusing on flexible designs and short lead times. Their piston and gear pump fillers are compatible with PET, HDPE, and glass containers. They also support OEM projects as a trusted sanitizing gel filling machine factory.

19. Barry-Wehmiller Packaging Systems (USA) ![]()

Barry-Wehmiller specializes in semi-automatic fillers, functioning as a small-scale hand sanitizer bottle filling machine factory. Their products are widely used in personal care, healthcare, and household chemicals. They’re known for robust quality and reliable after-sales support.

E-PAK Machinery is a U.S.-based hand sanitizer filling machine factory with decades of experience in viscous product packaging. Their servo-driven piston fillers are engineered for precision and hygiene. They now offer expanded services and support globally.

Conclusion

Selecting the right equipment for hand sanitizer production is essential for maintaining quality, efficiency, and regulatory compliance. Your choice should be based on the type of sanitizer—gel or liquid—the production volume, and the packaging format you plan to use.

For smaller operations or specialty batches, semi-automatic systems may be sufficient. Larger manufacturers will benefit from fully integrated filling lines that automate every step from bottle feeding to capping and labeling. It's also important to prioritize features like explosion-proof components, sanitary design, and flexible nozzle configurations to suit your product’s viscosity.

Ultimately, working with experienced machinery suppliers who understand your production needs will help ensure long-term success, consistent output, and high product standards.