Top 20 Fruit Juice Packaging Machine Manufacturers in 2025

Top 20 Fruit Juice Packaging Machine Manufacturers in 2025

Transforming fresh fruit into a shelf-ready beverage is a complex journey that culminates in a critical step: packaging. The choice of packaging machinery directly impacts a juice's shelf life, appeal, and marketability. For producers, navigating this technology raises key questions: What machines are needed? What do they cost? And what packaging materials work best? This guide explores the world of fruit juice packaging machinery, from initial processing to final seal.

What are the Machines Used in Fruit Juice Processing?

Fruit juice processing involves a sequence of machines before reaching the packaging stage. A typical line includes:

1. Washing & Sorting: Cleaners and graders for raw fruit.

2. Extraction & Pressing: Crushers, pulpers, and presses to obtain juice.

3. Clarification & Filtration: Decanters and filters to remove pulp and solids (for clear juices).

4. Pasteurization/Ultra-Pasteurization: Heat exchangers to destroy microorganisms and deactivate enzymes, crucial for

shelf stability.

5. Packaging Machine: The final unit that fills the processed juice into its container. This is the core product of

fruit juice packaging machine manufacturers, and ranges from simple fillers for local sales to aseptic lines for

global distribution. Downstream, labelers, coders, and case packers complete the line.

What is the Packaging Material for Fruit Juice?

The material choice dictates the required machine type and significantly impacts shelf life:

• Glass Bottles: Premium feel, excellent barrier properties. Requires a small juice packing machine manufacturers or

larger filler capable of gentle glass handling.

• PET Plastic Bottles: Lightweight, shatterproof, and widely used. Filled using gravity or piston fillers.

• Cartons (Tetra Pak): Multi-layer, aseptic packaging for long ambient shelf life. Requires a form-fill-seal machine.

• Pouches: A flexible, cost-effective option, popular for children's drinks and concentrates. The

juice pouch packing machine price is often lower than for rigid container lines, making it accessible. Stand-up

pouches are filled on vertical form-fill-seal (VFFS) machines.

What is the Cost of a Fruit Juice Packaging Machine?

Cost varies dramatically based on automation, speed, and packaging format:

• Small & Semi-Automatic Machines: Ideal for startups or craft producers. A tabletop piston filler or a basic pouch sealer

might cost $5,000 to $25,000. These are offered by small juice packing machine manufacturers.

• Mid-Range Automatic Fillers: For growing businesses. An automatic rotary piston filler with

4 nozzle juice packing machine manufacturers offering models in this range could cost between $30,000 and

$100,000.

• High-Speed/Aseptic Lines: For large-scale production. Fully integrated, high-speed lines from

automatic juice packing machine manufacturers, especially for cartons or aseptic bottles, can range from $200,000

to over $1 million.

Filling Technology and Mechanisms

The dominant technology for juice is volumetric piston filling. A piston retracts within a cylinder to draw a precise juice volume, then pushes it into the container. This handles pulp and varying viscosities with accuracy. For hot-fill juice (typically above 185°F), the machine incorporates heating jackets and a cooling tunnel. Aseptic filling involves sterilizing the container (with peroxide or steam) and filling in a sterile chamber.

Advantages and Benefits of Packaging Machines

Investing in proper packaging equipment delivers critical advantages:

• Extended Shelf Life: Hot-fill and aseptic technology stabilizes juice, preventing spoilage without refrigeration.

• Exceptional Accuracy: Volumetric filling ensures compliance with net content regulations and minimizes costly product

giveaway.

• Increased Production Speed: Automation from automatic juice packing machine manufacturers enables scaling from

hundreds to thousands of units per hour.

• Enhanced Hygiene & Safety: Sanitary design with CIP (Clean-in-Place) systems prevents contamination.

• Brand Consistency & Professionalism: Creates a uniform, leak-free, market-ready product that builds consumer trust.

• Operational Efficiency: Significantly reduces labor costs and physical waste compared to manual methods.

Troubleshooting and Maintenance Considerations

Juice, with its sugar and acid content, requires diligent machine care.

• Inaccurate Fills: Caused by pulp clogging valves, worn piston seals, or air in the product line.

• Leakage or Poor Seals: Check for damaged sealing jaws (on pouches), worn cap liners, or incorrect filling

temperatures affecting cap application.

• Product Degradation: In hot-fill lines, ensure correct holding temperature and time. In cold-fill lines, verify nitrogen

flushing (if used) to prevent oxidation.

A strict, preventive maintenance schedule is essential:

• Daily: Complete disassembly and cleaning of all product-contact parts (pistons, nozzles, fill valves) to prevent bacterial

growth and sticky residue buildup.

• Weekly: Inspection and replacement of seals, O-rings, and gaskets. Lubrication of moving parts with food-grade

lubricants.

• Monthly: Calibration of fill volumes, temperature sensors, and sealing parameters.

Partnering with reputable fruit juice packaging machine manufacturers ensures access to technical support and spare parts designed for the specific demands of juice, protecting both your investment and the quality of your product.

List of 20 Fruit Juice Packaging Machine Manufacturers

|

Address: Room 1905, Youyi Building, Xincheng Avenue, Cixi, Ningbo, Zhejiang, China |

|

| Mic Machinery is one of the established fruit juice packaging machine manufacturers, supplying pouch, bottle, and sachet packing solutions for juice producers. The company focuses on stable filling accuracy, hygienic structure design, and flexible customization. Its equipment supports different juice viscosities and packaging materials. Mic Machinery serves beverage factories seeking reliable and scalable packaging systems. |

|

Address: 152 Longquan Bay, Xueyan Town, Wujin, Changzhou, Jiangsu, China |

|

| BW Filling Machinery is globally recognized for its carton-based juice packaging solutions. The company provides integrated filling and sealing systems designed to protect product quality and shelf life. Its machines are widely used for ambient and chilled juice products. BW Filling Machinery solutions are suitable for high-capacity beverage manufacturers. |

|

Address: 2224 Wukesong Road, Sanxing town, Zhangjiagang, Jiangsu, China |

|

| Zhangjiagang Mic Machinery is active among automatic juice packing machine manufacturers, offering fully automated packaging lines. The company focuses on intelligent control systems and energy-efficient operation. Its machines support PET bottle and pouch juice packaging formats. Zhangjiagang Mic Machinery equipment is widely exported to global beverage markets. |

|

Address: Böhmerwaldstraße 5, 93073 Neutraubling, Bavaria, Germany |

|

| Krones AG specializes in beverage processing and packaging technology. Its juice packaging systems emphasize automation, production efficiency, and line integration. The company offers complete turnkey solutions from filling to final packaging. Krones equipment is commonly used by large international beverage brands. |

|

Address: 1535 S State Road 39, La Porte, Indiana, United States of America |

|

| APACKS provides integrated juice packaging solutions including filling, capping, and labeling. The company emphasizes production stability and reduced operational costs. Its machines are suitable for high-speed juice manufacturing lines. APACKS serves both domestic and international beverage producers. |

|

Address: Avenue de la Patrouille de France, 76930 Octeville-sur-Mer, Normandy, France |

|

| Sidel provides advanced packaging equipment for PET bottles and flexible containers. The company develops intelligent juice filling and packing solutions with strong focus on sustainability. Its systems deliver high-speed performance with precise volume control. Sidel machines are widely adopted in industrial juice production. |

|

Address: 50 Schoolhouse Road Somerset, New Jersey, United States of America |

|

| Cozzoli Machine Company supplies processing and packaging equipment for the food and beverage industry. Its juice packaging systems are designed for hygiene, efficiency, and easy maintenance. The company supports customized solutions for different juice formulations. Cozzoli equipment is trusted by large-scale food manufacturers. |

|

Address: Stuttgarter Straße 130, Waiblingen, Baden-Württemberg, Germany |

||

| Syntegon Technology GmbH offers advanced packaging technologies for liquid food products. Its juice packaging machines combine precision engineering with automation expertise. The company provides flexible solutions for bottles, pouches, and cartons. Syntegon systems are widely used in regulated food environments. |

|

Address: 4119 Fordleigh Road Baltimore, Maryland, United States of America |

||

| Filamatic is a well-known supplier of pouch packaging solutions. The company designs machines suitable for juice sachets and small-volume packaging. Its equipment emphasizes sealing reliability and accurate dosing. Filamatic machines are commonly used in emerging beverage markets. |

|

Address: Juchostrasse 20, 44143 Dortmund, Germany |

|

| KHS Group designs packaging machinery for liquid food and beverages. Its juice packaging equipment is known for hygiene-focused engineering and durable construction. The company supports both standalone machines and full production lines. KHS systems are used in medium to large juice bottling plants. |

|

Address: 2980 Scott St, Vista, CA 92081, United States |

|

| Accutek Packaging Equipment develops vertical form fill seal machines for liquid products. Its juice packaging solutions support multiple pouch sizes and formats. The company focuses on compact machine design and ease of operation. Accutek equipment is suitable for small to medium juice producers. |

|

Address: Via Italia, 43, Gessate Milano, Lombardy, Italy |

|

| Ronchi Mario S.p.A. provides flexible packaging machinery for liquid food applications. Its juice packing systems support automation and high-speed production. The company emphasizes modular designs and quick changeovers. Ronchi equipment is widely used in pouch-based juice packaging. |

|

Address: Via G. Garibaldi, 34N, Bonate Sotto, Lombardy, Italy |

|

| Comac manufactures pouch packing machines for food and beverage products. Its systems are commonly used by small juice packing machine manufacturers serving startups and regional brands. The company focuses on user-friendly controls and compact layouts. Comac machines are suitable for limited-space production facilities. |

|

Address: Olympus House, Mill Green Road, Haywards Heath, West Sussex, United Kingdom |

|

| Adelphi Packaging Machinery supplies filling and packaging equipment for liquid products. Its juice machines are designed for accuracy and long-term durability. The company supports customized configurations for different production needs. Adelphi equipment is used in both food and beverage industries. |

|

Address: N15 W23500 Stone Ridge Drive, Waukesha, Wisconsin, United States of America |

||

| Federal Mfg. is a global leader among juice packaging machine manufacturers, known for its automation and advanced engineering. Their systems handle a wide variety of juice formats with precision. They remain a competitive name in juice packing machine manufacturers worldwide. |

|

Address: Hofäckerstraße 9 Crailsheim, Baden-Württemberg, Germany |

|

|

Groninge specializes in filling and packaging machinery for liquids. Its juice packaging solutions emphasize hygienic design and efficient throughput. The company serves producers of fruit juices and flavored beverages. Groninge equipment is widely used in Europe and beyond. |

|

Address: Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa, Japan |

|

| Shibuya Corporation specializes in rotary pouch filling and sealing machines. Its equipment supports accurate dosing and stable sealing for juice packaging. The company offers solutions related to juice pouch packing machine price competitiveness. Shibuya machines are widely used in Asian beverage factories. |

|

Address: 15-39 130th St, College Point, New York, United States of America |

|

| Filling Equipment Company supplies packaging machinery for bottles, cans, and pouches. Its juice filling and packing systems offer reliable automation and precise control. The company focuses on flexible solutions for growing manufacturers. Filling Equipment Company equipment supports both manual and automatic lines. |

|

Barry-Wehmiller Packaging Systems Address: 8020 Forsyth Boulevard, St. Louis, Missouri, United States of America |

||

| Barry-Wehmiller Packaging Systems provides horizontal and vertical packaging solutions for juice products. Its machines support advanced pouch formats and high-speed operation. The company emphasizes innovation and digital integration. Barry-Wehmiller equipment is commonly used by premium beverage brands. |

|

Address: 1535 South State Road 39, La Porte, IN 46350, United States |

|

| E-PAK Machinery designs packaging machinery for liquid food applications. Its product range includes systems aligned with 4 nozzle juice packing machine manufacturers requirements. The company focuses on durability, simplicity, and cost efficiency. E-PAK machines are suitable for small to mid-sized juice producers. |

Global Distribution of Fruit Juice Packaging Machine Manufacturers by Country

| Country | Number of Companies | Share (%) |

|

USA | 8 | 40% |

|

Germany | 4 | 20% |

|

China | 3 |

15% |

|

Italy | 2 | 10% |

|

France | 1 | 5% |

|

United Kingdom | 1 | 5% |

|

Japan | 1 | 5% |

List of 6 Fruit Juice Packaging Machine Products

|

|

Juice Spout Pouch Filling Machine

A juice spout pouch filling machine is designed to accurately fill juice into spouted pouches. It ensures precise dosing, hygienic operation, and efficient production, making it ideal for beverage manufacturers producing convenient, ready-to-drink juice pouches. |

|

|

|

|

A juice sachet packing machine is used to accurately fill and seal juice into small sachets. It ensures precise dosing, hygienic packaging, and high efficiency, making it ideal for juice manufacturers and beverage production lines. |

|

|

|

|

A juice cup packaging machine is designed to fill and seal juice into cups efficiently and hygienically. It ensures accurate dosing, secure sealing, and high-speed production, making it ideal for beverage manufacturers producing ready-to-drink juice cups. |

|

|

|

|

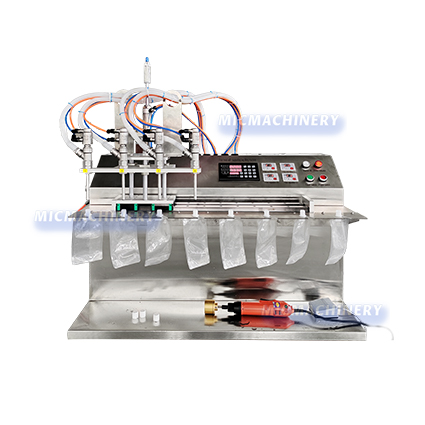

A juice pouch packing machine is designed to fill and seal juice into flexible pouches efficiently. It ensures accurate dosing, hygienic packaging, and high-speed production, making it ideal for beverage manufacturers looking to package juices in convenient pouch formats. |

|

|

|

|

Semi-auto Juice Spout Pouch Filling Machine

A semi-auto juice spout pouch filling machine is used to partially automate the filling of juice into spouted pouches. It combines manual and automated operations to ensure accurate dosing, hygienic packaging, and improved efficiency, making it suitable for small to medium-scale beverage production. |

|

|

|

|

Juice Spout Pouch Packing Machine

A juice spout pouch packing machine is used to fill and seal juice into pouches with spouts for easy pouring. It ensures accurate dosing, hygienic packaging, and efficient production, making it ideal for beverage manufacturers producing convenient, consumer-friendly juice pouches. |

|

|