Top 20 Drink Bottling Machine Manufacturers in 2025

Top 20 Drink Bottling Machine Manufacturers in 2025

The global beverage market relies on a seamless, efficient process to get drinks from the production line to the consumer. At the heart of this operation is the drink bottling machine, a sophisticated piece of engineering designed for speed, accuracy, and hygiene. For anyone in the beverage industry, key questions arise: What equipment is needed for a full bottling line? What types of machines are available? And how do they actually work? This guide provides a comprehensive overview of drink bottling technology.

What Equipment is Needed for Drink Bottling?

A complete drink bottling line is an integrated system of several machines working in concert. The core components include:

• Bottle Unscrambler: Orients and feeds empty bottles onto the conveyor.

• Air Rinser: Cleans bottles with jets of clean or ionized air to remove dust.

• Filling Machine: The central unit that dispenses the precise volume of product.

• Capping Machine: Applies and tightens screw caps or press-on lids.

• Labeling Machine: Applies product labels accurately.

• Packaging Machine: Packs finished bottles into cases or shrink-wrap trays.

Specialized cold drink bottle packing machine manufacturers often provide integrated solutions that bundle these components for carbonated beverage production.

What are the Different Types of Drink Bottling Machines?

Drink bottling machines are primarily categorized by their technology and level of automation:

• Gravity Fillers: Simple and cost-effective, best for still water and non-carbonated juices.

• Piston Fillers: Ideal for viscous products like syrups, smoothies, and pulpy juices, offering high accuracy.

• Pressure (Isobaric) Fillers: The essential technology for carbonated soft drinks, these machines use counter-pressure

to prevent foaming and CO₂ loss. This is the specialty of cold drink filling machine manufacturers and

soft drink bottling machine manufacturers.

• Vacuum Fillers: Used for thin, non-carbonated liquids, drawing product into the bottle by vacuum.

These systems are supplied by a wide range of drink filling machine manufacturers and drink bottling machine manufacturers, each catering to different market segments and product types.

How Do Drink Bottling Machines Work?

The bottling process is a continuous, automated sequence:

1. Bottle Handling & Cleaning: Bottles are fed onto the line and cleaned.

2. Filling: Bottles enter the filling carousel. The specific technology takes over:

◦ For carbonated drinks, the filler uses counter-pressure: the bottle is sealed and pressurized with CO₂ before the

product is gently injected.

◦ For non-carbonated drinks, gravity or volumetric pistons dispense the liquid.

3. Capping: Filled bottles move immediately to the capper, which applies closures to preserve freshness and prevent

contamination.

4. Labeling and Packaging: Bottles are labeled and packed for distribution, completing the process.

Filling Technology and Mechanisms

The two dominant mechanisms in drink bottling are:

• Volumetric Filling (Piston): A piston draws a precise volume of product from a reservoir and dispenses it into the

container. This is highly accurate for a wide range of viscosities.

• Level Filling (Gravity/Pressure): The liquid flows until it reaches a specific level in the container, at which point a sensor

or the mechanical design of the valve cuts off the flow. Pressure fillers adapt this principle for carbonated products.

Advantages and Benefits of Filling Machines

Investing in a bottling line from reputable drink filling machine manufacturers offers transformative advantages:

• High-Speed Production: Enables large-scale output that is impossible to achieve manually.

• Exceptional Accuracy: Ensures every bottle contains the exact same volume, minimizing product giveaway.

• Enhanced Hygiene & Safety: Constructed from food-grade stainless steel with CIP systems, reducing contamination

risk.

• Operational Cost Reduction: Significantly lowers labor requirements and minimizes product waste from spillage.

• Brand Consistency: Creates a uniform, professional product that builds consumer trust.

Troubleshooting and Maintenance Considerations

Proactive maintenance is crucial for minimizing downtime. Common issues include:

• Inaccurate Fills: Caused by worn piston seals, clogged valves, or incorrect pressure settings.

• Leakage: Typically results from damaged filling valves or misaligned capping heads.

• Foaming (in carbonated drinks): Often due to warm product temperature, low CO₂ pressure, or dirty bottles.

A strict preventive maintenance schedule is essential. This includes regular cleaning, lubrication, and inspection of seals and moving parts. The long-term reliability of the machine, a key consideration beyond the initial cold drink filling machine price, depends on this diligent upkeep. Partnering with established soft drink bottling machine manufacturers ensures access to technical support and genuine spare parts to maintain optimal performance.

List of 20 Drink Bottling Machine Manufacturers

|

Address: Room 1905, Youyi Building, Xincheng Avenue, Cixi, Ningbo, Zhejiang, China |

|

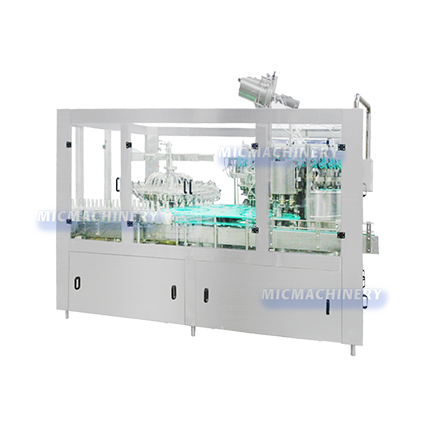

| Mic Machinery is a leading cold drink filling machine manufacturers brand offering versatile bottling solutions. Their equipment includes automatic and semi-automatic lines suitable for carbonated beverages, juices, and water. Recognized globally, Mic Machinery combines high precision with energy-efficient designs, making it one of the top drink bottling machine manufacturers. |

|

Address: 152 Longquan Bay, Xueyan Town, Wujin, Changzhou, Jiangsu, China |

|

| BW Filling Machinery is renowned for soft drink bottling machine manufacturers and aseptic beverage processing equipment. Their cold drink filling machine manufacturers lines focus on hygiene, energy efficiency, and user-friendly operation. BW Filling Machinery machines are widely deployed in juice and soft drink bottling facilities worldwide. |

|

Address: 2224 Wukesong Road, Sanxing town, Zhangjiagang, Jiangsu, China |

|

| Zhangjiagang Mic Machinery provides cutting-edge drink bottling machine manufacturers systems for beverage production globally. Their drink filling machine manufacturers equipment supports carbonated and non-carbonated beverages with precise filling control. Zhangjiagang Mic Machinery’s semi-automatic and fully automatic machines ensure minimal product loss and maximum productivity. |

|

Address: Böhmerwaldstraße 5, 93073 Neutraubling, Bavaria, Germany |

|

| Krones AG, based in Germany, is a top-tier soft drink bottling machine manufacturers offering comprehensive filling and packaging solutions. Their drink filling machine manufacturers systems are used worldwide in beverage production lines. Krones machines are celebrated for their high speed, hygiene, and reliability. |

|

Address: 1535 S State Road 39, La Porte, Indiana, United States of America |

|

| APACKS offers reliable cold drink filling machine manufacturers suitable for carbonated drinks and still beverages. Their cold drink bottle packing machine manufacturers systems are designed for high-speed production and minimal downtime. APACKS’s innovative solutions cater to both small breweries and large beverage companies. |

|

Address: Avenue de la Patrouille de France, 76930 Octeville-sur-Mer, Normandy, France |

|

| Sidel Group is a French manufacturer recognized among cold drink filling machine manufacturers for its innovative PET and glass bottle filling systems. Their cold drink bottle packing machine manufacturers solutions integrate advanced automation and energy-saving technology. Sidel machines are widely used for soft drinks, juices, and water. |

|

Address: 50 Schoolhouse Road Somerset, New Jersey, United States of America |

|

| Cozzoli Machine Company is recognized among drink filling machine manufacturers for their flexible and durable PET and glass bottling lines. Their machines ensure accurate fill levels and maintain carbonation integrity. Cozzoli is also praised for its energy-efficient and environmentally conscious designs. |

|

Address: Stuttgarter Straße 130, Waiblingen, Baden-Württemberg, Germany |

||

| Syntegon Technology GmbH is among the respected cold drink filling machine manufacturers, delivering semi-automatic and fully automatic filling solutions. Their cold drink bottle packing machine manufacturers systems cater to both glass and PET bottles. Syntegon focuses on hygienic, high-speed, and precise filling technology. |

|

Address: 4119 Fordleigh Road Baltimore, Maryland, United States of America |

||

| Filamatic is a recognized drink bottling machine manufacturers brand providing cost-effective bottling solutions. Their drink filling machine manufacturers equipment includes both liquid and carbonated beverage lines. Filamatic machines are known for durability and ease of maintenance. |

|

Address: Juchostrasse 20, 44143 Dortmund, Germany |

|

| KHS GmbH, based in Germany, is a notable soft drink bottling machine manufacturers and drink filling machine manufacturers provider. Their lines handle carbonated beverages with advanced temperature and carbonation control. KHS is known for durable machines with high operational efficiency. |

|

Address: 2980 Scott St, Vista, CA 92081, United States |

|

| Accutek Packaging Equipment is a trusted soft drink bottling machine manufacturers company specializing in small and medium-scale beverage plants. Their cold drink filling machine manufacturers solutions ensure consistent fill levels and product safety. Accutek combines affordability with reliable technology. |

|

Address: Via Italia, 43, Gessate Milano, Lombardy, Italy |

|

| Ronchi Mario S.p.A. is a leading drink bottling machine manufacturers company from Italy, specializing in fully automated beverage lines. Their cold drink filling machine price is competitive for small to mid-size beverage producers. Ronchi machines are engineered for high reliability and precise filling. |

|

Address: Via G. Garibaldi, 34N, Bonate Sotto, Lombardy, Italy |

|

| Comac provides advanced drink bottling machine manufacturers for carbonated and non-carbonated beverages. Their cold drink bottle packing machine manufacturers systems are ideal for large-scale production lines. Comac focuses on precision filling and efficient operational workflows. |

|

Address: Olympus House, Mill Green Road, Haywards Heath, West Sussex, United Kingdom |

|

| Adelphi Packaging Machinery is a top cold drink filling machine manufacturers offering automated beverage filling and capping solutions. Their machines are suitable for glass, PET, and cans. Adelphi equipment ensures accurate carbonation levels and hygienic filling standards. |

|

Address: N15 W23500 Stone Ridge Drive, Waukesha, Wisconsin, United States of America |

||

| Federal Mfg. is a well-known cold drink filling machine manufacturers providing affordable yet durable solutions. Their cold drink bottle packing machine manufacturers lines handle various bottle sizes with accurate filling. The machines are designed for small to medium-scale beverage operations. |

|

Address: Hofäckerstraße 9 Crailsheim, Baden-Württemberg, Germany |

|

|

Groninge specializes in drink bottling machine manufacturers for carbonated beverages. Their drink filling machine manufacturers solutions focus on high-speed production and easy maintenance. Groninge machines are popular among European soft drink producers. |

|

Address: Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa, Japan |

|

| Shibuya Corporation offers competitive cold drink filling machine manufacturers lines for PET and glass bottles. Their cold drink filling machine price makes them attractive for new beverage startups. Shibuya emphasizes hygiene, speed, and user-friendly operation. |

|

Address: 15-39 130th St, College Point, New York, United States of America |

|

| Filling Equipment Company is a trusted soft drink bottling machine manufacturers company offering semi-automatic and fully automatic solutions. Their drink bottling machine manufacturers lines support multiple bottle formats and beverage types. Filling Equipment Company machines are valued for precision and minimal product waste. |

|

Barry-Wehmiller Packaging Systems Address: 8020 Forsyth Boulevard, St. Louis, Missouri, United States of America |

||

| Barry-Wehmiller Packaging Systems is a global leader in cold drink filling machine manufacturers and packaging solutions. Their drink filling machine manufacturers are recognized for advanced automation, hygienic design, and long-term reliability. Barry-Wehmiller systems are widely used in large-scale soft drink bottling facilities. |

|

Address: 1535 South State Road 39, La Porte, IN 46350, United States |

|

| E-PAK Machinery is recognized among drink filling machine manufacturers and soft drink bottling machine manufacturers. They provide semi-automatic and fully automated filling lines with high reliability. E-PAK equipment is widely used in beverage plants seeking precision and productivity. |

Global Distribution of Drink Bottling Machine Manufacturers by Country

| Country | Number of Companies | Share (%) |

|

USA | 8 | 40% |

|

Germany | 4 | 20% |

|

China | 3 |

15% |

|

Italy | 2 | 10% |

|

France | 1 | 5% |

|

United Kingdom | 1 | 5% |

|

Japan | 1 | 5% |

List of 14 Drink Bottling Machine Products

|

|

12-12-1 Carbonated Drink Bottling Machine

A 12-12-1 carbonated drink bottling machine features 12 rinsing heads, 12 filling heads, and 1 capping head to rinse, fill, and cap bottles in one process. It ensures accurate filling, hygienic operation, and stable performance for small to medium-scale production. |

|

|

|

|

18-18-1 Carbonated Drink Bottling Machine

An 18-18-1 carbonated drink bottling machine is equipped with 18 rinsing heads, 18 filling heads, and 1 capping head to rinse, fill, and cap bottles in a single process. It ensures precise filling, hygienic operation, and reliable performance for medium-scale production. |

|

|

|

|

24-24-6 Carbonated Drink Bottling Machine

A 24-24-6 carbonated drink bottling machine features 24 rinsing heads, 24 filling heads, and 6 capping heads to efficiently rinse, fill, and cap bottles in one integrated process. It ensures accurate filling, hygienic operation, and high-speed production for large-scale beverage manufacturing. |

|

|

|

|

18-18-6 Carbonated Beverage Bottling Machine

An 18-18-6 carbonated drink bottling machine is equipped with 18 rinsing heads, 18 filling heads, and 6 capping heads to complete rinsing, filling, and capping in one line. It ensures precise filling, hygienic operation, and efficient production for medium to large-scale beverage manufacturing. |

|

|

|

|

Semi-auto Carbonated Drink Bottling Machine

A semi-auto carbonated drink bottling machine combines manual loading with automated rinsing, filling, and capping. It ensures accurate filling, hygienic operation, and is suitable for small to medium-scale production. |

|

|

|

|

18-18-6 Non-carbonated Drink Bottling Machine

An 18-18-6 non-carbonated drink bottling machine has 18 rinsing heads, 18 filling heads, and 6 capping heads to efficiently rinse, fill, and cap bottles. It ensures precise filling, hygienic operation, and high-speed production. |

|

|

|

|

24-18-6 Non-carbonated Drink Bottling Machine

A 24-18-6 non-carbonated drink bottling machine features 24 rinsing heads, 18 filling heads, and 6 capping heads to efficiently rinse, fill, and cap bottles. It ensures accurate filling, hygienic operation, and high-speed production for large-scale beverage manufacturing. |

|

|

|

|

14-12-5 Non-carbonated Drink Bottling Machine

A 14-12-5 non-carbonated drink bottling machine is equipped with 14 rinsing heads, 12 filling heads, and 5 capping heads to efficiently rinse, fill, and cap bottles. It ensures accurate filling, hygienic operation, and reliable performance for medium-scale beverage production. |

|

|

|

|

Linear Non-carbonated Drink Bottling Machine

A linear non-carbonated drink bottling machine is designed to rinse, fill, and cap bottles in a straight-line layout. It ensures accurate filling, hygienic operation, and efficient production, making it suitable for small to medium-scale beverage manufacturing. |

|

|

|

|

32-32-8 Carbonated Drink Bottling Machine

A 32-32-8 carbonated drink bottling machine features 32 rinsing heads, 32 filling heads, and 8 capping heads to efficiently rinse, fill, and cap bottles in one integrated process. It ensures precise filling, hygienic operation, and high-speed production for large-scale beverage manufacturing. |

|

|

|

|

18-18-1 Carbonated Drink Bottling Machine

An 18-18-1 carbonated drink bottle filling machine is equipped with 18 rinsing heads, 18 filling heads, and 1 capping head to rinse, fill, and cap bottles in a single process. It ensures accurate filling, hygienic operation, and stable performance for medium-scale production. |

|

|

|

|

8-8-3 Non-carbonated Drink Bottling Machine

An 8-8-3 non-carbonated drink bottling machine features 8 rinsing heads, 8 filling heads, and 3 capping heads to efficiently rinse, fill, and cap bottles. It ensures precise filling, hygienic operation, and reliable performance for small to medium-scale beverage production. |

|

|

|

|

12-1 Non-carbonated Drink Bottling Machine

A 12-1 non-carbonated drink bottling machine is equipped with 12 filling heads and 1 capping head to efficiently fill and seal bottles. It ensures accurate filling, hygienic operation, and stable performance for small to medium-scale beverage production.

|

|

|

|

|

18-18-6 Non-carbonated Drink Bottling Machine

An 18-18-6 non-carbonated drink bottle filling machine features 18 rinsing heads, 18 filling heads, and 6 capping heads to efficiently rinse, fill, and cap bottles. It ensures precise filling, hygienic operation, and high-speed production for medium to large-scale beverage manufacturing. |

|

|