Top 20 Drink Bottling Machine Companies in 2026

Top 20 Drink Bottling Machine Companies in 2026

From sparkling water and sodas to juices and enhanced beverages, the drink industry thrives on efficient, reliable packaging. The cornerstone of this operation is the drink bottling machine, a sophisticated piece of equipment designed for speed, hygiene, and precision. For any business entering or scaling in this market, understanding the technology is crucial. This guide answers the key questions: what types of machines exist, how do they function, and what is the required investment?

What are the Types of Drink Bottling Machines?

Drink bottling machines are categorized by their operating principle, which is chosen based on the drink's characteristics (carbonation, viscosity, pulp) and the desired production speed. The main types include:

• Gravity Fillers: The simplest type, where liquid flows by weight from an elevated tank into bottles. Ideal for still, non-

viscous drinks like water and some juices.

• Piston Fillers: Use a volumetric piston and cylinder to draw and dispense an exact liquid volume. Excellent for pulpy

juices, dairy drinks, and syrups due to high accuracy regardless of viscosity.

• Pressure (Counter-Pressure) Fillers: Essential for carbonated soft drinks, beers, and sparkling waters. These

machines, the specialty of cold drink filling machine companies and soft drink bottling machine companies, use

pressurized CO₂ to fill bottles without losing carbonation or causing excess foam.

• Vacuum Fillers: Suitable for still beverages in glass bottles, using suction to draw product into the container, ensuring a

clean fill.

These systems are supplied by a wide range of drink filling machine companies and drink bottling machine companies, each offering different levels of automation from semi-automatic to high-speed rotary lines.

How Does the Drink Bottling Machine Work?

The bottling process is an automated, sequential operation. While specifics vary by technology, a standard automatic line follows these core steps:

1. Bottle Unscrambling & Cleaning: Empty bottles are oriented and fed onto a conveyor, then inverted and purged with

clean air or a sterile water mist.

2. Filling: Bottles enter the filling carousel. Here, the specific technology takes over:

◦ For carbonated drinks, bottles are sealed and pressurized before the product is gently injected (counter-pressure

filling).

◦ For non-carbonated drinks, gravity, piston, or vacuum mechanisms dispense the liquid to a precise level.

3. Capping: Immediately after filling, bottles move to a capping station where closures (screw caps, sports caps, crowns)

are applied and tightened.

4. Labeling & Packaging: Bottles are labeled, coded, and then packed into cases or trays—a stage often supported by

integrated solutions from cold drink bottle packing machine companies.

What is the Cost of a Drink Bottling Machine?

The cost of a drink bottling machine is highly variable, driven by automation, speed, and technology. As a general guide:

• Semi-Automatic/Small-Scale Machines: Ideal for startups and low-volume production. Prices typically range

from $10,000 to $50,000.

• Automatic In-Line or Rotary Fillers: For medium-scale operations requiring higher output. These systems from drink

bottling machine companies usually cost between $50,000 and $250,000.

• High-Speed, Fully Integrated Lines: For large-scale beverage production, featuring speeds of thousands of bottles per

hour. Complete lines, especially for carbonated drinks from soft drink bottling machine companies, can range

from $300,000 to over $1 million.

Filling Technology and Mechanisms

The core mechanisms revolve around achieving accurate volume control:

• Volumetric Control (Piston): A piston retracts to draw a set volume from a product tank, then advances to push it into

the bottle. This is highly precise.

• Level Sensing (Gravity/Pressure): Liquid flows until it reaches a sensor or the valve outlet, at which point the flow

stops. Pressure fillers adapt this with a pressurized gas blanket to control carbonated products.

Advantages and Benefits of Bottling Machines

Investing in equipment from established drink filling machine companies delivers significant operational advantages:

• High Production Speed & Scalability: Automates the most labor-intensive step, enabling massive output increases.

• Exceptional Accuracy & Consistency: Ensures every bottle contains the exact same volume, ensuring compliance and

reducing product giveaway.

• Enhanced Hygiene & Food Safety: Constructed from food-grade stainless steel with Clean-in-Place (CIP) systems,

minimizing contamination risk.

• Reduced Operational Costs: Lowers long-term labor requirements and minimizes product waste from spillage.

• Professional Brand Image: Creates a uniform, reliable product that builds consumer trust and brand value.

Troubleshooting and Maintenance Considerations

Proactive maintenance is essential for maximizing uptime and machine life. Common issues include:

• Inaccurate Fills: Caused by worn piston seals, clogged valves, or incorrect pressure/timing settings.

• Leakage or Dripping: Typically results from damaged filling nozzles, worn O-rings, or misaligned capping heads.

• Foaming (in carbonated drinks): Often due to warm product temperature, low CO₂ pressure, or dirty bottles.

A strict preventive maintenance schedule is crucial. This includes daily cleaning (CIP), regular lubrication, and scheduled inspection and replacement of wear parts like seals and gaskets. Following protocols from your drink bottling machine companies or cold drink filling machine companies protects your investment and ensures consistent, high-quality production. Proper upkeep safeguards both your machinery and the reputation of your brand.

List of 20 Drink Bottling Machine Companies

|

Address: Room 1905, Youyi Building, Xincheng Avenue, Cixi, Ningbo, Zhejiang, China |

|

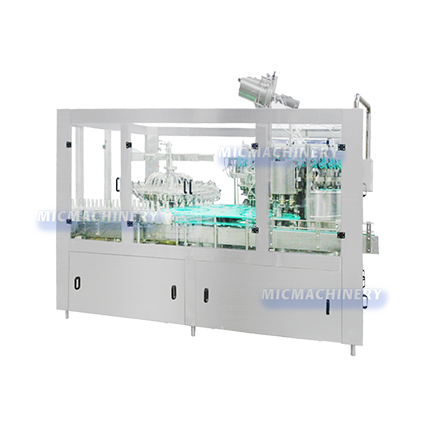

| Mic Machinery is a leading manufacturer of bottling and packaging solutions, specializing in high-efficiency beverage production lines. They provide reliable equipment for a variety of beverages, from juices to carbonated drinks. Known for precision engineering and innovative designs, Mic Machinery stands out among drink bottling machine companies. Their machines are trusted globally for performance and durability. |

|

Address: 152 Longquan Bay, Xueyan Town, Wujin, Changzhou, Jiangsu, China |

|

| BW Filling Machinery offers a broad range of filling solutions for both small-scale and industrial beverage operations. Their equipment focuses on reducing waste and improving production speed. They are highly regarded in the market for their advanced automation and customization capabilities. |

|

Address: 2224 Wukesong Road, Sanxing town, Zhangjiagang, Jiangsu, China |

|

| Zhangjiagang Mic Machinery produces versatile beverage filling lines suitable for bottles of all shapes and sizes. They emphasize high-quality materials, efficiency, and easy maintenance to ensure long-term performance. Their solutions meet the growing demands of beverage manufacturers seeking reliable operations. Many global clients rely on their precision-engineered machines for smooth production. |

|

Address: Böhmerwaldstraße 5, 93073 Neutraubling, Bavaria, Germany |

|

| Krones AG is a global leader in beverage filling technology, delivering fully integrated production lines for soft drinks, juices, and water. Their machines combine sustainability with high output efficiency and precision engineering. Krones also provides extensive support and training for operators. Beverage manufacturers around the world depend on their innovative and automated solutions. |

|

Address: 1535 S State Road 39, La Porte, Indiana, United States of America |

|

| APACKS manufactures a wide range of beverage packaging and filling machines for various production scales. Their solutions combine speed, accuracy, and flexibility to accommodate different bottle types. APACKS is well-known for innovative designs and user-friendly operation. Their equipment is widely adopted by companies looking for cost-effective, reliable filling lines. |

|

Address: Avenue de la Patrouille de France, 76930 Octeville-sur-Mer, Normandy, France |

|

| Sidel offers cutting-edge bottling systems that cover the full beverage production process, from filling to labeling. Their machines ensure hygiene, consistency, and high-speed operation. Sidel is considered among the top cold drink filling machine companies for their advanced automation and global service network. Beverage producers choose Sidel for precision and long-term efficiency. |

|

Address: 50 Schoolhouse Road Somerset, New Jersey, United States of America |

|

| Cozzoli Machine Company specializes in precision filling and capping equipment for beverage and liquid products. They provide high-speed, accurate filling for small bottles, vials, and specialty containers. Their machines are trusted in both beverage and pharmaceutical industries. Cozzoli is recognized for durability, automation, and ease of operation in demanding production environments. |

|

Address: Stuttgarter Straße 130, Waiblingen, Baden-Württemberg, Germany |

||

| Syntegon Technology GmbH delivers advanced solutions for beverage packaging and bottling. Their machines are known for reliable operation, automated process control, and flexible configurations. Syntegon supports manufacturers in optimizing efficiency while reducing production downtime. Their innovative designs make them a preferred choice for modern beverage lines worldwide. |

|

Address: 4119 Fordleigh Road Baltimore, Maryland, United States of America |

||

| Filamatic provides versatile filling and capping systems for beverages, with an emphasis on compact and scalable solutions. Their machines are designed to improve productivity, reduce waste, and minimize downtime. Filamatic is widely adopted by medium and large beverage producers. They are recognized for reliability, high speed, and user-friendly operation. |

|

Address: Juchostrasse 20, 44143 Dortmund, Germany |

|

| KHS GmbH offers state-of-the-art bottling systems for soft drinks, water, and beer. Their equipment integrates hygiene, automation, and high-speed filling to meet industrial demands. KHS is considered a key player among soft drink bottling machine companies worldwide. Manufacturers rely on their solutions for quality, precision, and consistency. |

|

Address: 2980 Scott St, Vista, CA 92081, United States |

|

| Accutek Packaging Equipment specializes in modular filling systems for beverages and liquid products. Their machines are cost-effective, efficient, and adaptable to various production requirements. Accutek emphasizes ease of use, minimal maintenance, and reliability. They are trusted by small and medium beverage manufacturers looking for practical bottling solutions. |

|

Address: Via Italia, 43, Gessate Milano, Lombardy, Italy |

|

| Ronchi Mario S.p.A. provides high-quality bottling machinery for beverages and other liquid products. Their focus is on innovation, precision, and energy efficiency. The company delivers machines that help manufacturers achieve reliable and consistent production. Beverage producers worldwide appreciate their expertise and comprehensive support. |

|

Address: Via G. Garibaldi, 34N, Bonate Sotto, Lombardy, Italy |

|

| Comac manufactures fully automated beverage filling and packaging lines. Their machines are designed for speed, flexibility, and minimal maintenance requirements. Comac’s equipment is popular in both carbonated and non-carbonated beverage production. The company is recognized for integrating advanced technology into user-friendly, reliable systems. |

|

Address: Olympus House, Mill Green Road, Haywards Heath, West Sussex, United Kingdom |

|

| Adelphi Packaging Machinery offers a wide range of filling and bottling solutions for various liquid products. Their machines focus on efficiency, reliability, and easy operation. Adelphi also emphasizes customization to meet specific production needs. Beverage manufacturers value their innovative designs and consistent performance. |

|

Address: N15 W23500 Stone Ridge Drive, Waukesha, Wisconsin, United States of America |

||

| Federal Mfg. specializes in beverage filling solutions with an emphasis on automation and productivity. Their machines are robust, scalable, and simple to maintain. Federal Mfg. provides equipment for both small-scale operations and large industrial lines. Their systems are known for accuracy, efficiency, and long-term durability. |

|

Address: Hofäckerstraße 9 Crailsheim, Baden-Württemberg, Germany |

|

|

Groninge produces high-precision filling and capping machines for beverages, pharmaceuticals, and personal care products. Their machines offer flexible configurations and reliable operation under demanding conditions. Groninger is praised for advanced technology that supports high-speed production. Manufacturers choose them for efficiency, precision, and consistent quality. |

|

Address: Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa, Japan |

|

| Shibuya Corporation delivers innovative beverage filling systems with compact, efficient designs suitable for small bottles. Their equipment provides high-speed operation and precise control over production. Shibuya’s solutions are cost-effective and highly reliable. Many beverage manufacturers rely on their machines for small-batch and large-scale production. |

|

Address: 15-39 130th St, College Point, New York, United States of America |

|

| Filling Equipment Company provides dependable solutions for filling and packaging beverages and liquids. Their machines are designed for accurate, hygienic, and high-speed operation. They are recognized among drink filling machine companies for consistent quality. Beverage producers trust them for both small and large production lines. |

|

Barry-Wehmiller Packaging Systems Address: 8020 Forsyth Boulevard, St. Louis, Missouri, United States of America |

||

| Barry-Wehmiller Packaging Systems supplies complete beverage filling and packaging solutions. Their equipment integrates automation, energy efficiency, and smooth production workflow. Barry-Wehmiller machines are widely adopted in global beverage plants. Their innovative designs ensure high output while maintaining product integrity. |

|

Address: 1535 South State Road 39, La Porte, IN 46350, United States |

|

| E-PAK Machinery designs filling and capping machines for beverages and other liquids. Their systems prioritize efficiency, hygiene, and durability. E-PAK is recognized as one of the leading cold drink bottle packing machine companies in the industry. Beverage manufacturers value their high-speed, reliable, and easy-to-maintain equipment. |

Global Distribution of Drink Bottling Machine Companies by Country

| Country | Number of Companies | Share (%) |

|

USA | 8 | 40% |

|

Germany | 4 | 20% |

|

China | 3 |

15% |

|

Italy | 2 | 10% |

|

France | 1 | 5% |

|

United Kingdom | 1 | 5% |

|

Japan | 1 | 5% |

List of 14 Drink Bottling Machine Products

|

|

12-12-1 Carbonated Drink Bottling Machine

A 12-12-1 carbonated drink bottling machine features 12 rinsing heads, 12 filling heads, and 1 capping head to rinse, fill, and cap bottles in one process. It ensures accurate filling, hygienic operation, and stable performance for small to medium-scale production. |

|

|

|

|

18-18-1 Carbonated Drink Bottling Machine

An 18-18-1 carbonated drink bottling machine is equipped with 18 rinsing heads, 18 filling heads, and 1 capping head to rinse, fill, and cap bottles in a single process. It ensures precise filling, hygienic operation, and reliable performance for medium-scale production. |

|

|

|

|

24-24-6 Carbonated Drink Bottling Machine

A 24-24-6 carbonated drink bottling machine features 24 rinsing heads, 24 filling heads, and 6 capping heads to efficiently rinse, fill, and cap bottles in one integrated process. It ensures accurate filling, hygienic operation, and high-speed production for large-scale beverage manufacturing. |

|

|

|

|

18-18-6 Carbonated Beverage Bottling Machine

An 18-18-6 carbonated drink bottling machine is equipped with 18 rinsing heads, 18 filling heads, and 6 capping heads to complete rinsing, filling, and capping in one line. It ensures precise filling, hygienic operation, and efficient production for medium to large-scale beverage manufacturing. |

|

|

|

|

Semi-auto Carbonated Drink Bottling Machine

A semi-auto carbonated drink bottling machine combines manual loading with automated rinsing, filling, and capping. It ensures accurate filling, hygienic operation, and is suitable for small to medium-scale production. |

|

|

|

|

18-18-6 Non-carbonated Drink Bottling Machine

An 18-18-6 non-carbonated drink bottling machine has 18 rinsing heads, 18 filling heads, and 6 capping heads to efficiently rinse, fill, and cap bottles. It ensures precise filling, hygienic operation, and high-speed production. |

|

|

|

|

24-18-6 Non-carbonated Drink Bottling Machine

A 24-18-6 non-carbonated drink bottling machine features 24 rinsing heads, 18 filling heads, and 6 capping heads to efficiently rinse, fill, and cap bottles. It ensures accurate filling, hygienic operation, and high-speed production for large-scale beverage manufacturing. |

|

|

|

|

14-12-5 Non-carbonated Drink Bottling Machine

A 14-12-5 non-carbonated drink bottling machine is equipped with 14 rinsing heads, 12 filling heads, and 5 capping heads to efficiently rinse, fill, and cap bottles. It ensures accurate filling, hygienic operation, and reliable performance for medium-scale beverage production. |

|

|

|

|

Linear Non-carbonated Drink Bottling Machine

A linear non-carbonated drink bottling machine is designed to rinse, fill, and cap bottles in a straight-line layout. It ensures accurate filling, hygienic operation, and efficient production, making it suitable for small to medium-scale beverage manufacturing. |

|

|

|

|

32-32-8 Carbonated Drink Bottling Machine

A 32-32-8 carbonated drink bottling machine features 32 rinsing heads, 32 filling heads, and 8 capping heads to efficiently rinse, fill, and cap bottles in one integrated process. It ensures precise filling, hygienic operation, and high-speed production for large-scale beverage manufacturing. |

|

|

|

|

18-18-1 Carbonated Drink Bottling Machine

An 18-18-1 carbonated drink bottle filling machine is equipped with 18 rinsing heads, 18 filling heads, and 1 capping head to rinse, fill, and cap bottles in a single process. It ensures accurate filling, hygienic operation, and stable performance for medium-scale production. |

|

|

|

|

8-8-3 Non-carbonated Drink Bottling Machine

An 8-8-3 non-carbonated drink bottling machine features 8 rinsing heads, 8 filling heads, and 3 capping heads to efficiently rinse, fill, and cap bottles. It ensures precise filling, hygienic operation, and reliable performance for small to medium-scale beverage production. |

|

|

|

|

12-1 Non-carbonated Drink Bottling Machine

A 12-1 non-carbonated drink bottling machine is equipped with 12 filling heads and 1 capping head to efficiently fill and seal bottles. It ensures accurate filling, hygienic operation, and stable performance for small to medium-scale beverage production.

|

|

|

|

|

18-18-6 Non-carbonated Drink Bottling Machine

An 18-18-6 non-carbonated drink bottle filling machine features 18 rinsing heads, 18 filling heads, and 6 capping heads to efficiently rinse, fill, and cap bottles. It ensures precise filling, hygienic operation, and high-speed production for medium to large-scale beverage manufacturing. |

|

|