Top 20 Beer Filling Machine Manufacturers in 2025

Top 20 Beer Filling Machine Manufacturers in 2025

The journey from fermentation tank to a perfectly packaged beer hinges on one critical piece of equipment: the beer filling machine. For brewers, understanding this technology is key to preserving quality and scaling production. This leads to several fundamental questions: What different types of fillers are available? What is the core principle behind their operation? And how do they actually work? This guide delves into the mechanics, benefits, and operational nuances of beer filling systems.

What are the Different Types of Beer Filling Machines?

Beer filling machines are categorized by their level of automation and design, each suited to different production scales:

• Gravity Fillers: Simple, often manual machines where beer flows by gravity. Best for small-scale, non-carbonated styles

but risky for carbonated beers due to high oxygen pickup.

• Counter-Pressure Bottle Fillers: The industry standard for quality. These machines pressurize the container before

filling to prevent CO₂ loss and oxygen ingress. They range from semi-automatic single-head units to fully automated systems.

• Isobaric Canning Lines: Similar to counter-pressure but optimized for cans, these are the preferred choice for modern

packaging, often supplied by beer packaging machine manufacturers.

• Rotary Fillers: High-speed systems where bottles or cans travel around a circular carousel, undergoing filling and

capping in a continuous motion. These are the domain of automatic beer filler manufacturers.

Specialized craft beer filling machine manufacturers often focus on smaller, more versatile systems that protect delicate beer profiles.

What is the Principle of a Beer Filling Machine?

The universal principle governing all modern beer fillers is isobaric (counter-pressure) filling. The core objective is to transfer beer from a pressurized tank into a container without disturbing the dissolved carbon dioxide (CO₂) and while minimizing exposure to oxygen. This is achieved by creating a pressure equilibrium between the product tank and the container before any liquid flows.

How Does a Beer Filling Machine Work?

The isobaric filling process is a precise, multi-stage operation:

1. Evacuation & Purging: The empty bottle or can is sealed against the filling valve. Air is evacuated, and the container is

purged with CO₂ to create an inert, pressurized environment.

2. Pressure Equalization: The pressure inside the container is raised to match the exact pressure in the beer brite tank.

This is the "isobaric" state.

3. Filling: With pressure equal, the liquid valve opens. The beer flows gently and smoothly into the container without

foaming.

4. Liquid Cut-Off & Decompression: When the beer reaches the predetermined fill level, the liquid valve closes. The gas

pressure in the bottle's neck is then slowly released ("snifted") to prevent foaming when the container is released.

5. Transfer to Seaming/Capping: The filled container is immediately conveyed to the seamer or capper to create an

airtight seal.

This entire integrated process is engineered by beer filling line manufacturers and beer filling equipment manufacturers.

Filling Technology and Mechanisms

The critical component is the filling valve, engineered to separately manage gas and liquid flows. Modern valves are designed for gentle beer handling and are often integrated with Clean-in-Place (CIP) systems for sanitation. The precision of these valves is what defines the quality of equipment from leading automatic beer filling machine manufacturers.

Advantages and Benefits of Filling Machines

Investing in a proper beer filler from reputable beer filling machine manufacturers offers transformative benefits:

• Preserved Freshness & Flavor: Dramatically reduces oxygen pickup, which is the primary cause of flavor staling.

• Carbonation Retention: Maintains the intended level of carbonation (volumes of CO₂) by preventing breakout during

filling.

• High Efficiency and Scalability: Automated lines from beer packaging equipment manufacturers enable high-volume

production to meet market demand.

• Brand Consistency: Ensures every bottle or can has the same fill level, carbonation, and quality, building consumer

trust.

• Reduced Product Waste: Precision filling minimizes spillage and overfilling, saving valuable product.

Troubleshooting and Maintenance Considerations

Proactive maintenance is essential for protecting beer quality. Common issues include:

• High Dissolved Oxygen (DO): Often caused by inefficient purging, leaks in CO₂ lines, or worn filler valve seals.

• Excessive Foaming: Typically a result of warm beer temperature, incorrect counter-pressure, or dirty containers.

• Inconsistent Fill Levels: Can be due to clogged filler valves, fluctuating product pressure, or faulty sensors.

A rigorous preventive maintenance schedule, as recommended by beer filling equipment manufacturers, is crucial. This includes daily CIP cycles, lubrication, and inspection of seals and moving parts to ensure longevity and consistent performance of the equipment.

List of 20 Beer Filling Machine Manufacturers

|

Address: Room 1905, Youyi Building, Xincheng Avenue, Cixi, Ningbo, Zhejiang, China |

|

| Mic Machinery is one of the most trusted beer filling machine manufacturers in China, providing full packaging line solutions for bottles, cans, and kegs. The company produces high-performance automatic beer filling machine manufacturers systems with seamless integration of rinsing, filling, and capping. Known for turnkey brewing solutions, Mic Machinery’s beer filling equipment manufacturers portfolio ensures consistent quality and operational efficiency for both craft and large-scale breweries. |

|

Address: 152 Longquan Bay, Xueyan Town, Wujin, Changzhou, Jiangsu, China |

|

| BW Filling Machinery provides cutting-edge technology for craft beer filling machine manufacturers. Its compact designs allow smaller breweries to achieve consistent results without sacrificing quality. BW Filling Machinery’s systems are known for easy operation, making it a popular choice for growing brewers. |

|

Address: 2224 Wukesong Road, Sanxing town, Zhangjiagang, Jiangsu, China |

|

| Zhangjiagang Mic Machinery is a well-established name in the field of beer packaging machine manufacturers with strong engineering expertise. Their filling and processing systems cater to high hygiene standards demanded by the beverage industry. Zhangjiagang Mic Machinery also develops eco-friendly beer packaging equipment manufacturers solutions for breweries seeking energy efficiency and product safety. |

|

Address: Böhmerwaldstraße 5, 93073 Neutraubling, Bavaria, Germany |

|

| Krones AG, based in Germany, is a leader among beer filling machine manufacturers globally. The company’s beer filling line manufacturers technology includes modular systems that enhance production flexibility. Their focus on sustainability and intelligent automation sets them apart in the brewing equipment industry. |

|

Address: 1535 S State Road 39, La Porte, Indiana, United States of America |

|

| APACKS offers complete brewery automation systems as a top beer filling line manufacturers brand in North America. Their filling lines are designed for flexibility, precision, and efficiency. The company’s automatic beer filler manufacturers solutions are ideal for mid-size brewers scaling up operations. |

|

Address: Avenue de la Patrouille de France, 76930 Octeville-sur-Mer, Normandy, France |

|

| Sidel is a global name among beer filling machine manufacturers offering state-of-the-art bottling lines. The brand’s technology includes beer packaging equipment manufacturers solutions that integrate automation, inspection, and smart maintenance. Sidel’s systems are trusted by multinational beverage producers for efficiency and reliability. |

|

Address: 50 Schoolhouse Road Somerset, New Jersey, United States of America |

|

| Cozzoli Machine Company is one of the largest American beer filling equipment manufacturers, providing PET and glass bottle filling solutions. The brand integrates intelligent control systems to optimize production efficiency. Its innovative technology helps breweries maintain flavor integrity and reduce waste. |

|

Address: Stuttgarter Straße 130, Waiblingen, Baden-Württemberg, Germany |

||

| Syntegon Technology GmbH, a German company, produces versatile filling systems for liquids, including beer. Recognized among leading automatic beer filling machine manufacturers, it offers both volumetric and gravity-filling solutions. Syntegon’s durable equipment supports consistent packaging quality over long production runs. |

|

Address: 4119 Fordleigh Road Baltimore, Maryland, United States of America |

||

| Filamatic is a respected beer bottling equipment manufacturers name that has specialized in precision filling systems for decades. Their robust technology ensures foam-free, accurate filling of bottles and kegs. The company’s advanced controls help minimize oxygen exposure, preserving beer freshness. |

|

Address: Juchostrasse 20, 44143 Dortmund, Germany |

|

| KHS GmbH is recognized among top automatic beer filling machine manufacturers for its precision-engineered bottling and canning systems. The company emphasizes modular designs, ensuring adaptability to various production scales. With decades of experience, KHS has become synonymous with reliability in beer filling equipment manufacturers technologies. |

|

Address: 2980 Scott St, Vista, CA 92081, United States |

|

| Accutek Packaging Equipment is known among top beer filling line manufacturers for its reliable carbonation and filling systems. The company’s compact beer fillers are ideal for premium and craft producers. Accutek emphasizes quality assurance and low oxygen pickup in every design. |

|

Address: Via Italia, 43, Gessate Milano, Lombardy, Italy |

|

| Ronchi Mario S.p.A., from Italy, offers high-speed filling and packaging lines for beverages. As leading beer packaging equipment manufacturers, they focus on hygienic design and energy efficiency. Their integrated systems are used by major beverage companies worldwide. |

|

Address: Via G. Garibaldi, 34N, Bonate Sotto, Lombardy, Italy |

|

| Comac, based in Italy, is a global supplier of beer filling machine manufacturers solutions, specializing in small- and large-capacity systems. Its beer bottling line manufacturers machines are used by both craft and industrial breweries. The company’s automated keg and can lines guarantee superior filling accuracy and product preservation. |

|

Address: Olympus House, Mill Green Road, Haywards Heath, West Sussex, United Kingdom |

|

| Adelphi Packaging Machinery is an emerging name among craft beer filling machine manufacturers. It specializes in designing and building custom brewhouses and canning lines for artisanal producers. Their systems balance high-tech innovation with handcrafted precision. |

|

Address: N15 W23500 Stone Ridge Drive, Waukesha, Wisconsin, United States of America |

||

| Federal Mfg., one of USA’s top beer filling machine manufacturers, provides full beverage production lines including water, juice, and beer. Its beer packaging machine manufacturers technology ensures efficiency and cleanliness during filling. The company serves both domestic and international markets. |

|

Address: Hofäckerstraße 9 Crailsheim, Baden-Württemberg, Germany |

|

|

Groninge has established a global reputation as reliable beer filling line manufacturers with automated systems for beverage plants. Their engineering ensures reduced spillage and enhanced efficiency. The company supports full installation, maintenance, and training services. |

|

Address: Ko-58 Mameda-Honmachi, Kanazawa, Ishikawa, Japan |

|

| Shibuya Corporation offers compact solutions for small breweries and beverage producers. Recognized as one of the automatic beer filler manufacturers, it combines American design with affordability. Their inline bottle fillers maintain accuracy, consistency, and sanitation. |

|

Address: 15-39 130th St, College Point, New York, United States of America |

|

| Filling Equipment Company is well-known for its tabletop and semi-automatic beer bottlers. As one of the top automatic beer filling machine manufacturers, their compact units are ideal for low to medium-volume production. The company’s flexible design supports bottles, cans, and growlers. |

|

Barry-Wehmiller Packaging Systems Address: 8020 Forsyth Boulevard, St. Louis, Missouri, United States of America |

||

| Barry-Wehmiller Packaging Systems is one of the prominent beer packaging machine manufacturers offering bottle, can, and keg filling lines. Their equipment is tailored for microbreweries and craft operations that need reliable automation. The company also provides semi-automatic and manual options for start-up breweries. |

|

Address: 1535 South State Road 39, La Porte, IN 46350, United States |

|

| E-PAK Machinery, located in the USA, stands out among beer filling equipment manufacturers for its innovative canning technology. Their canning lines support fast changeovers and high precision. E-PAK’s modular approach allows breweries to scale production smoothly. |

Global Distribution of Beer Filling Machine Manufacturers by Country

| Country | Number of Companies | Share (%) |

|

USA | 8 | 40% |

|

Germany | 4 | 20% |

|

China | 3 |

15% |

|

Italy | 2 | 10% |

|

France | 1 | 5% |

|

United Kingdom | 1 | 5% |

|

Japan | 1 | 5% |

List of 11 Beer Filling Machine Products

|

|

An 18-6 beer can filling machine features 18 filling heads and 6 sealing heads, combining filling and sealing in one integrated system. It ensures precise filling, hygienic operation, and high-speed performance, making it ideal for medium to large-scale beer can production. |

|

|

|

|

12-12-1 Beer Bottle Filling Machine

A 12-12-1 beer bottle filling machine includes 12 rinsing heads, 12 filling heads, and 1 capping head to complete rinsing, filling, and capping in one operation. It ensures accurate filling, hygienic production, and reliable performance, making it ideal for small to medium-scale breweries. |

|

|

|

|

18-18-1 Beer Bottle Filling Machine

An 18-18-1 beer bottle filling machine is designed with 18 rinsing heads, 18 filling heads, and 1 capping head to perform rinsing, filling, and capping in one continuous process. It ensures precise filling, hygienic operation, and stable performance, making it ideal for medium-scale brewery production. |

|

|

|

|

18-18-6 Beer Bottle Filling Machine

An 18-18-6 beer bottle filling machine features 18 rinsing heads, 18 filling heads, and 6 capping heads to integrate rinsing, filling, and capping in one system. It ensures accurate filling, hygienic operation, and high-speed performance, making it ideal for medium to large-scale beer production lines. |

|

|

|

|

A 24-6 beer can filling machine is equipped with 24 filling heads and 6 sealing heads to efficiently fill and seal beer cans in one integrated process. It ensures precise filling, hygienic operation, and high-speed production, making it ideal for large-scale beer can manufacturing. |

|

|

|

|

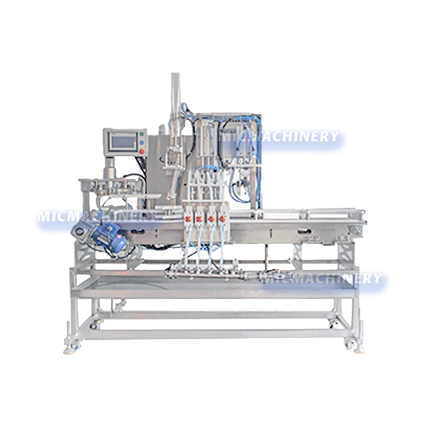

Semi-auto Linear Beer Can Filling Machine

A semi-auto linear beer can filling machine partially automates the filling of beer cans in a linear arrangement. It combines manual loading with automated filling and sealing to ensure accurate dosing, hygienic operation, and improved efficiency, making it suitable for small to medium-scale beer can production. |

|

|

|

|

Semi-auto Beer Can Filling Machine

A semi-auto beer can filling machine partially automates the filling and sealing of beer cans. It combines manual handling with automated processes to ensure accurate filling, hygienic operation, and improved efficiency, making it ideal for small to medium-scale beer can production. |

|

|

|

|

Semi-auto Beer Bottle Filling Machine

A semi-auto beer bottle filling machine partially automates the rinsing, filling, and capping of beer bottles. It combines manual handling with automated processes to ensure accurate filling, hygienic operation, and improved efficiency, making it suitable for small to medium-scale breweries. |

|

|

|

|

Semi-auto Beer Can Seaming Machine

A semi-auto beer can seaming machine is used to manually place cans while automatically sealing them with precision. It ensures tight, leak-proof seams, hygienic operation, and improved efficiency, making it ideal for small to medium-scale beer can production. |

|

|

|

|

A 12-1 beer can filling machine is equipped with 12 filling heads and 1 sealing head to efficiently fill and seal beer cans in a single process. It ensures accurate filling, hygienic operation, and stable performance, making it ideal for small to medium-scale beer can production. |

|

|

|

|

An 18-1 beer can filling machine features 18 filling heads and 1 sealing head to efficiently fill and seal beer cans in one integrated process. It ensures precise filling, hygienic operation, and reliable performance, making it ideal for medium-scale beer can production. |

|

|